Tension Control Considerations for High-Temperature Superconducting Tapes

Improve quality and increase efficiency in HTS Tape manufacturing.

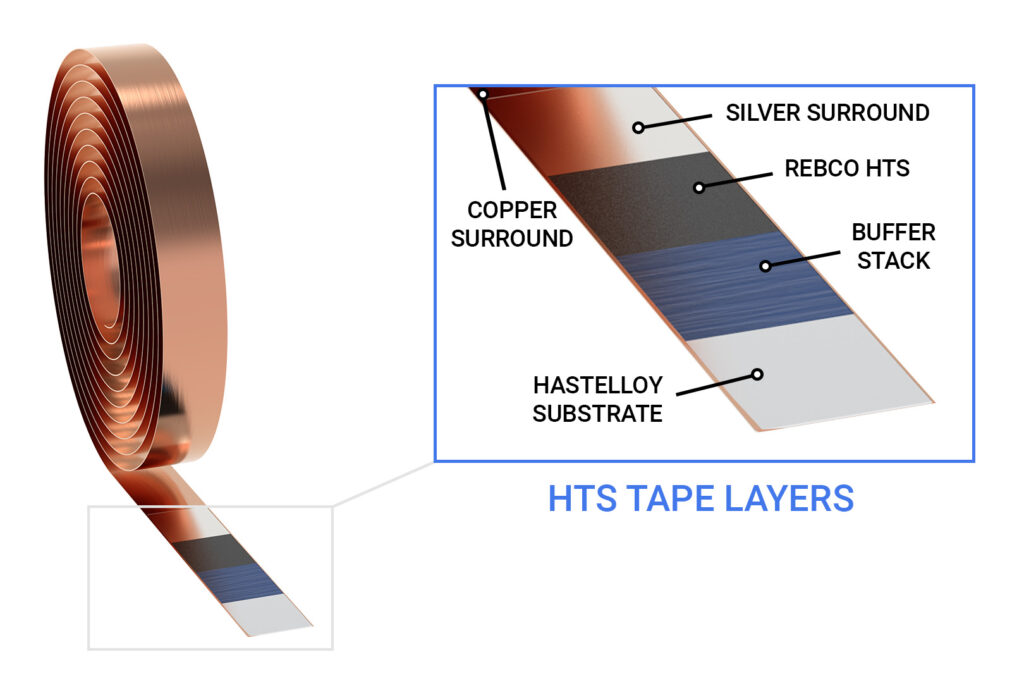

If you’re in the business of making high-temperature superconductor (HTS) tapes—particularly REBCO types—you’re not just handling a web. You’re handling a molecularly sensitive, multi-layered, high-value web where tension control isn’t optional—it’s foundational.

Let’s walk through the process to learn how tension control is crucial for HTS tape—a key component of particle accelerators, fusion power systems and medical imaging equipment.

SUBSTRATE HANDLING: THE FOUNDATION OF MOLECULAR ORDER

REBCO tapes begin with a metal substrate, often a nickel alloy, which is rolled into a thin, flexible tape. This substrate is then textured and coated with buffer layers to prepare for the growth of the superconducting film.

Here’s the kicker: the molecular alignment of the REBCO layer depends on the crystalline texture of the substrate. And that texture can be compromised by mechanical strain—which is directly influenced by tension.

Too much tension: You stretch the substrate, distort the crystal lattice, and compromise the superconducting pathway.

Too little tension: You get wrinkles, misalignment, and coating defects.

Web handling rule: Use closed-loop tension control with load cells and feedback to maintain strain below 0.1%. That’s your sweet spot.

DEPOSITION OF BUFFER AND SUPERCONDUCTING LAYERS

Whether you’re using PLD, MOCVD, or CSD, the deposition of REBCO requires a flat, stable web. Any flutter, vibration, or lateral instability will show up as non-uniform growth, grain misalignment, or pinholes.

This is where tension control becomes a defect prevention tool. Use short spans and low-inertia rollers to minimize flutter. Consider vacuum rollers or air flotation tables for ultra-sensitive zones. Monitor web position and tension in real time—don’t guess.

THERMAL PROCESSING: ANNEALING AND OXYGENATION

REBCO tapes often undergo high-temperature annealing to activate superconductivity. But here’s the rub: thermal expansion can cause the tape to curl, buckle, or delaminate if tension isn’t properly managed.

Web handling rule: Use zoned tension control with thermal compensation. Match tension to the thermal profile of the oven. Don’t let the tape fight the heat.

SLITTING AND REWINDING: PROTECTING THE FINAL PRODUCT

After deposition and annealing, the tape is slit and wound. This is where mechanical damage can sneak in. High tension during slitting can cause edge fray or microcracks. Poor rewind tension can lead to telescoping, blocking, or even cracking of the brittle REBCO layer.

Web handling rule: Use taper tension control during rewind. Start high, end low. Keep the roll tight but not crushed.

PERFORMANCE GAINS FROM GOOD TENSION CONTROL

Let’s be clear: tension control isn’t just about avoiding defects, it’s about enabling performance.

Better molecular alignment → higher critical current.

Fewer coating defects → longer tape life.

Stable roll geometry → easier integration into magnets or cables.

In short, tension control is a process enabler and a performance amplifier.

FINAL THOUGHTS

If you’re making REBCO tapes and you’re not thinking about tension control, you’re leaving quality on the table. This isn’t just web handling—it’s molecular choreography. And tension is the conductor.

Dover Flexo Electronics industry-leading solutions, including the Ribbon TriWheel™ Tension Load Cell, SteadyWeb 6™ Controller, and TA500 tension amplifier, empower manufacturers to optimize these processes, delivering measurable improvements in quality and profitability.

By investing in DFE’s tension control technology, HTS Tape producers also leverage the experience of DFE’s team of applications engineers, dedicated to achieving high-performance results tailored to the customer’s specific manufacturing process.

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

RESOURCES

High-Temperature Superconducting Tape Tension Control (PDF)