VNW Very Narrow Web Tension Transducer / Load Cell

A compact, heavy-duty cantilevered tension sensing load cell for measuring ribbon, filament, wire, cable or very narrow web processes.

The VNW Very Narrow Web transducer combines the robustness of DFE’s Model C transducer with the choice of mounting styles and wheel options from the cantilevered RFA load cell design. The VNW’s maximum 400 lb load rating extends it’s capability beyond the RFA’s limit of 150 lbs, allowing for higher tension applications such as steel belt and tire cord.

A VNW transducer is cantilever-mounted on process machinery for unwind, rewind, or intermediate (process) zone applications. Tension is measured by high-output semiconductor strain gauges housed internally on a dual cantilevered transducer beam and connected in a full Wheatstone bridge configuration. As the ribbon or filament passes over the rotating transport wheel, the force of the substrate on the wheel shaft causes a minute deflection of the transducer beam. The resulting change in strain gauge resistance yields a voltage output from the transducer that is proportional to tension. The transducer output is then amplified by a DFE indicator or automatic tension controller for tension measurement or complete closed-loop tension control.

The VNW transducer’s standard configuration incorporates an aluminum beam with a stainless steel housing and shaft holder. The five mounting styles offered are: Screw, Flange, Pillow-Block, Piloted-Flange and Through-Frame.

Wheels are shaft-mounted with the shaft inserted into the transducer’s bore and secured by set screws. The shaft insertion depth can be adjusted (+/- 0.25 inch) for proper alignment of the wheel with the web or filament. The standard electrical connector is positioned at 6 o’clock (inline with force) but other positions can be specified relative to the force direction.

For the measurement of web widths wider than 4 inches, see the Narrow Web Transducer.

FEATURES

• 5 year tension-free warranty

• Highly accurate and reliable semiconductor strain gauge technology

• Versatile and easy-to-install

• Wheel face lengths up to 4 inches

• High performance design and materials for long life

• Load Ratings from 10 – 400 lbs (45 – 1800 N) with wide operating range

• Special wheels are available

BENEFITS

• Accurate tension measurement of any narrow web, ribbon or filament

• Improved product quality and consistency from any web or filament process

• Reduced material waste

• Higher production with less downtime

Do you have more questions about this product?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

ELECTRICAL

Excitation: 5 VDC Max (Std), 10 VDC Max (XR Option)

Output: 100 mV/V, Nominal

Strain Gauge Resistance: 100 Ohms, Nominal

Circuit Configuration (Pair): Full Wheatstone Bridge

Non-Repeatability: ±1/4% Full Span (FS)

Combined Non-Linearity & Hysteresis:

±1/2% Full Span (FS)

Temperature Range: -10°F to 200°F (-23°C to 93°C)

Temperature Coefficient:

.02% FS per °F, Typical (.036% FS per °C)

Mating Electrical Connector (Mil-Spec) P/N:

106-0050

Connector Pin Assignment:

A = Signal Output (-) D = Signal Output (+)

B = Excitation (+) E = Excitation (-)

C = Excitation (-) F = Excitation (+)

MECHANICAL

Overload Capacity: 1200 lbs (5338 N)

Deflection of Sensor Beam: .005 Inch (.127 mm), Max

Materials: 6061, 7075-T6 Aluminum; 303,

304 Stainless Steel; Black Oxide Alloy Steel

Connector Positions (by mounting type):

Screw / Flange / Piloted-Flange: 6:00, 12:00

Pillow-Block: 12:00, Rear

Through-Frame: Rear

Load Ratings: 10, 25, 50, 100, 200, 400 lbs

(45, 111, 222, 445, 890, 1779 N)

Wheel Kits:

Ceramic Filament Wheel – P/N: 603-4108

Aluminum Filament Wheel – P/N: 603-1678

1 Inch Ribbon Wheel – P/N: 603-1672

2 Inch Ribbon Wheel – P/N: 603-1673

3 Inch Ribbon Wheel – P/N: 603-1674

4 Inch Ribbon Wheel – P/N: 603-1675

Adapter Wheel – P/N: 603-1679

REFERENCE DOCUMENTS

LOAD CALCULATOR

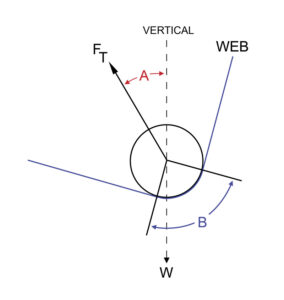

Force Above Horizontal

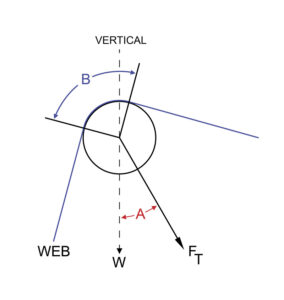

LOAD CALCULATOR

Force Below Horizontal

Weight of ceramic filament wheel is 0.27 lb (121 grams) including bearings and fasteners.

Weight of aluminum filament wheel is 0.49 lb (222 grams) including bearings and fasteners.

Weight of ribbon wheels are from 0.45 lb (204 grams) to 0.75 lb (341 g) including bearings and fasteners.

Weight of adapter wheel is 0.65 lb (295 grams) including bearings and fasteners.

Click the preferred product in the table below, then select CAD format to download.

Complete the form to enable your file download

| Product Code | Size | Mounting Style | Load Rating | Connector Position |

| VNW2-S-10-6 | 1 | Screw / Bolt | 10 lbs (45 N) | 6:00 |

| VNW2-S-25-6 | 1 | Screw / Bolt | 25 lbs (111 N) | 6:00 |

| VNW2-S-50-6 | 1 | Screw / Bolt | 50 lbs (222 N) | 6:00 |

| VNW2-S-100-6 | 1 | Screw / Bolt | 100 lbs (445 N) | 6:00 |

| VNW2-S-200-6 | 1 | Screw / Bolt | 200 lbs (890 N) | 6:00 |

| VNW2-S-400-6 | 1 | Screw / Bolt | 400 lbs (1779 N) | 6:00 |

| VNW2-S-10-6-MMS | 1 | Screw / Bolt | 10 lbs (45 N) | 6:00 |

| VNW2-S-25-6-MMS | 1 | Screw / Bolt | 25 lbs (111 N) | 6:00 |

| VNW2-S-50-6-MMS | 1 | Screw / Bolt | 50 lbs (222 N) | 6:00 |

| VNW2-S-100-6-MMS | 1 | Screw / Bolt | 100 lbs (445 N) | 6:00 |

| VNW2-S-200-6-MMS | 1 | Screw / Bolt | 200 lbs (890 N) | 6:00 |

| VNW2-S-400-6-MMS | 1 | Screw / Bolt | 400 lbs (1779 N) | 6:00 |

| VNW2-FL-10-6 | 1 | Flange | 10 lbs (45 N) | 6:00 |

| VNW2-FL-25-6 | 1 | Flange | 25 lbs (111 N) | 6:00 |

| VNW2-FL-50-6 | 1 | Flange | 50 lbs (222 N) | 6:00 |

| VNW2-FL-100-6 | 1 | Flange | 100 lbs (445 N) | 6:00 |

| VNW2-FL-200-6 | 1 | Flange | 200 lbs (890 N) | 6:00 |

| VNW2-FL-400-6 | 1 | Flange | 400 lbs (1779 N) | 6:00 |

| VNW2-PB-10-REAR | 1 | Pillow Block | 10 lbs (45 N) | Rear |

| VNW2-PB-25-REAR | 1 | Pillow Block | 25 lbs (111 N) | Rear |

| VNW2-PB-50-REAR | 1 | Pillow Block | 50 lbs (222 N) | Rear |

| VNW2-PB-100-REAR | 1 | Pillow Block | 100 lbs (445 N) | Rear |

| VNW2-PB-200-REAR | 1 | Pillow Block | 200 lbs (890 N) | Rear |

| VNW2-PB-400-REAR | 1 | Pillow Block | 400 lbs (1779 N) | Rear |

| VNW2-PB-10-12 | 1 | Pillow Block | 10 lbs (45 N) | 12:00 |

| VNW2-PB-25-12 | 1 | Pillow Block | 25 lbs (111 N) | 12:00 |

| VNW2-PB-50-12 | 1 | Pillow Block | 50 lbs (222 N) | 12:00 |

| VNW2-PB-100-12 | 1 | Pillow Block | 100 lbs (445 N) | 12:00 |

| VNW2-PB-200-12 | 1 | Pillow Block | 200 lbs (890 N) | 12:00 |

| VNW2-PB-400-12 | 1 | Pillow Block | 400 lbs (1779 N) | 12:00 |

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.