LT Low Tension Transducer / Load Cell

A compact, low-tension load cell that converts filament or ribbon force into a proportionate tension output signal.

The Low Tension Transducer is a high-performance load cell often used in filament, fiber, ribbon and wire processing applications that require tension measurement or control at very low levels.

The LT Transducer is available in either a stackable housing configuration or a threaded housing (M36 x 2) with two locking jam nuts. The threaded housing installs easily into a hole on your machine frame. Its locking nut system allows force direction to be changed by simply loosening the nuts and adjusting the transducer to a desired position.

Standard LT transducer wheels are hard coat anodized aluminum or solid ceramic. They are durable, low-inertia and fitted with instrument-grade ball bearings. The LT transducer may also be purchased without a wheel for customers who prefer their own design.

HOW IT WORKS

The Low Tension Transducer is an electro-mechanical sensor device that converts filament or ribbon tension into a DC voltage proportional to tension. The voltage output can be amplified in external electronic circuitry and displayed as actual tension on an analog or digital meter in pounds, ounces, grams, kilograms or newtons. LT Transducer output can also be fed to a DFE automatic tension controller to control tension in a closed-loop.

CAPABILITIES

• Two mounting styles: threaded bolt or stackable

• Special wheels are available

• Loading ratings from 50g to 2000g (2 oz to 4.4 lbs)

FEATURES

• 5 year tension-free warranty

• Highly accurate and reliable semiconductor strain gauge technology

• Six load ratings, from 50 grams to 2000 grams

• Aluminum construction

• Choice of filament wheel, ribbon wheel, or stationary pin

• Two mounting styles – stackable or threaded (through-hole)

• High output provides resistance to electrical noise

• Strong construction

• Use with any DFE tension amplifier, indicator or controller

BENEFITS

• Helps reduce waste and improve quality and productivity

• Compact size allows transducer to fit into small spaces

• Low cost

• Ultra-low break-away torque (1.5 g-cm or 0.02 oz-inches) means no sliding or scratching of filament on wheel

• Stackable – several transducers fit into a small space

• Two mounting styles to fit any application

• Measures very low tension accurately

Do you have more questions about this product?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

ELECTRICAL

Excitation: 10 VDC Max

Output: 50 mV/V, Nominal

Strain Gauges: Semiconductor, 800 Ohms, Nominal

Circuit Configuration: Full Wheatstone Bridge

Non-Repeatability: ±1/4% Full Span (FS)

Combined Non-Linearity & Hysteresis:

±1/2% Full Span (FS)

Temperature Range: -10°F to 200°F (-23°C to 93°C)

Temperature Coefficient:

.02% FS per °F, Typical (.036% FS per °C)

Mating Electrical Connector (Mil-Spec) P/N:

106-0050

Connector Pin Assignment:

A = Signal Output (-) D = Signal Output (+)

B = Excitation (+) E = Excitation (-)

C = Excitation (-) F = Excitation (+)

MECHANICAL

Overload Capacity: 9 Kg (89 N)

Deflection of Sensor Beam: .02 inch (0.5 mm), Typical

Materials: Stainless Steel & Aluminum

Break-Away Torque: 0.02 oz-in (1.5 gram-cm), Typical

Connector Position: Rear

Basic Dynamic Load Rating of Bearings:

136 Kg (1340 N)

REFERENCE DOCUMENTS

LOAD CALCULATOR

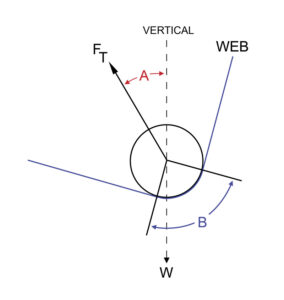

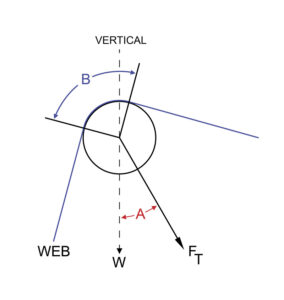

Force Above Horizontal

LOAD CALCULATOR

Force Below Horizontal

Weight of filament wheel is 14 grams including bearings and fasteners.

Weight of ribbon wheel is 18 grams including bearings and fasteners.

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.