Corona Treater Tension Control

The importance of tension control in corona treatment processes.

What is Corona Treatment?

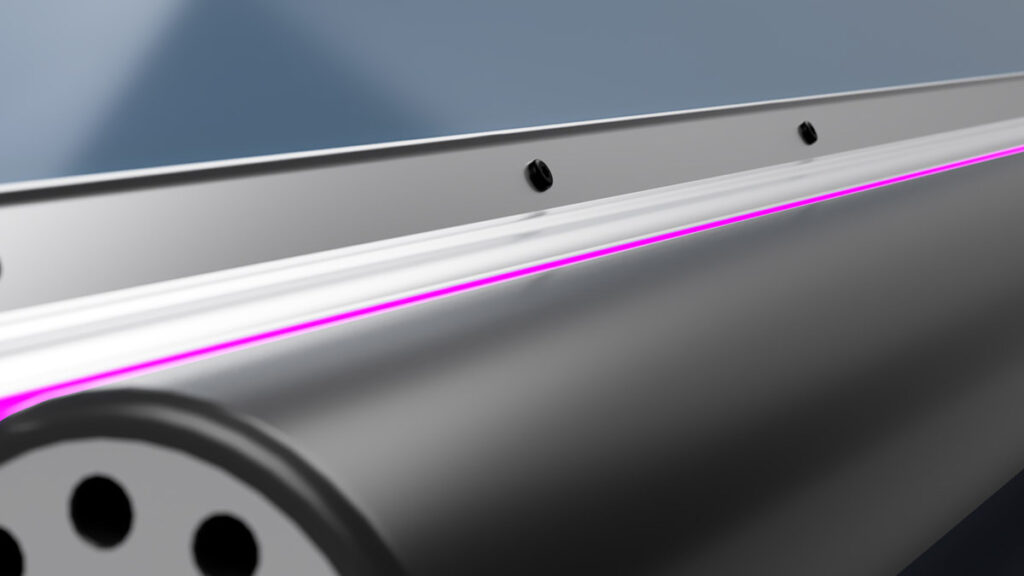

A corona treater consists of a high voltage power supply and a treater station. Corona treatment is a surface modification technique using a high voltage discharge to increase the surface energy (dyne level) in plastics, cloth, paper, etc. Many of these products are non-porous with low surface tensions causing them to resist bonding with inks, adhesives and coatings. Corona treatment improves the dyne levels in the product to be treated, allowing high quality, consistent results, in an economical manner.

Potential Problems

If product curling or wrinkling develops in the treater zone, an excessive air gap on the back side of the web can cause unintentional back-side treatment. This reduces the watt density on the side to be treated, lowering the products dyne level. The result is a finished product with inconsistent quality.

Potential Solution: Web Tension Control

Precise corona treatment depends on consistent web tension which, if not controlled properly, can hinder the process. Integrating a controller, load cells, and a brake on a treater line can often support corona treating at higher speeds, while reducing waste caused by curling or wrinkling.

Turn-key Corona Treater tension control systems typically incorporate:

• A closed-loop tension controller such as the SteadyWeb™ 6

• A load cell such as the Tension Roll® Transducer

• A Pneumatic Brake, Magnetic Particle Brake, Clutch or Motor Drive System

Customers integrating tension control with a PLC most often utilize:

• A load cell signal amplifier such as the TA1 TrueTension™ Amplifier

• A load cell such as the Tension Roll® Transducer, a pair of convertible load cells such as the Model C Series Transducers or Under Pillow Block Transducers such as the Model F Series

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

RESOURCES

Application Note: Corona Treater Tension Control (PDF)