TR Tension Roll® Transducer / Load Cell

A custom length tension-sensing load cell roller system designed for versatility, accuracy, reliability, easy maintenance and installation.

Ultimate performance and robust reliability set the Tension Roll® Transducer apart from other sensing solutions on the market. A dead-shaft idler roller with tension sensors (semiconductor strain gauge load cells) integrated into each roll end, the Tension Roll® transducer is ideal for installation on original equipment or for retrofits since it arrives pre-assembled and ready-to-install between the facing sides of a machine frame.

With the TR transducer the engineering time required to size the unit to the machine frame prior to installation is significantly lower than installing standard shaft-end load cells or tension transducers onto an idler roll. A consolidated connector allows cable runs to be reduced to a single side of the machine frame, further simplifying installation.

For web presses and machines that run an extreme range of materials and tensions, the Tension Roll® transducer can be mounted in a pair of Model C shaft-end tension transducers. This allows one range of tension to be measured by the Tension Roll® sensors, while a higher load range can be measured using the externally-mounted tension transducers. This feature is convenient in the rare cases when a machine’s tension range exceeds the 100:1 maximum-to-minimum tension ratio of DFE’s extended range option.

Tension Roll® transducers are available in three (3) standard roll materials including aluminum, steel or stainless steel. Special roll surface materials and coatings are also available.

Available roll face widths range from from 6 inches to 120 inches in length, able to fit most application requirements. Roll diameters from 2.25 inches (57mm) to 6 inches (152mm) are standard. Diameters larger than 6 inches can be special-ordered.

CAPABILITIES

• Load ratings from 12 – 400 lbs (55 – 1800 N)

• High overload capacity – up to 3000 lbs (13300 N)

• DFE controllers and indicators are available with a Dual Calibration feature for accepting calibration parameters from two sets of tension transducers, allowing users a wider range of tension measurement

FEATURES & BENEFITS

• 5 year tension-free warranty

• Highly accurate and reliable semiconductor strain gauge technology

• Measures actual web tension – eliminates guess work and runs correct tension consistently

• Helps reduce or eliminate web breakage, stretching, registration and length problems by making it possible to control tension accurately

• Dual cantilever sensing beams provides high strength and accuracy even at low tension

• Temperature compensated for stable output

• CE marked – Meets European low voltage (73/23/EEC) and EMC (89/336/EEC) directives

• Stainless steel and aluminum construction for excellent corrosion resistance

Note of Interest: The TR Tension Roll® Transducer is also referred to by some of our customers as the Dover Roller, the Tension Roller and sometimes the Tension Measurement Roller. Any way you like it, this is the easiest way for printers and manufacturers to measure web tension on a press, converting line or coating line.

Do you need a Tension Roll® transducer with multiple transducer segments across the roll face? DFE makes a custom Tension Roll®, called a Segmented Tension Roll® transducer that measures web tension at multiple positions across the roll face at increments you specify. Find out more here.

Do you have more questions about this product?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

ELECTRICAL

Excitation: 5 VDC Max (Std), 10 VDC Max (XR Option)

Output: 100 mV/V, Nominal

Strain Gauge Resistance: 100 Ohms, Nominal

Circuit Configuration (Pair): Full Wheatstone Bridge

Non-Repeatability: ±1/4% Full Span (FS)

Combined Non-Linearity & Hysteresis:

±1/2% Full Span (FS)

Temperature Range: -10°F to 200°F (-23°C to 93°C)

Temperature Coefficient:

.02% FS per °F, Typical (.036% FS per °C)

Mating Electrical Connector (Mil-Spec) P/N:

106-0050

Connector Pin Assignment:

A = Signal Output (-) D = Signal Output (+)

B = Excitation (+) E = Excitation (-)

C = Excitation (-) F = Excitation (+)

MECHANICAL

Roll Material / Diameter:

6061 Aluminum: 3 Inch, 3 Inch Low Inertia, 4 Inch, 5 Inch, 6 Inch

1020 Series Steel: 3 Inch, 4 Inch, 5 Inch, 6 Inch

304 Stainless Steel: 3 Inch, 4 Inch, 5 Inch, 6 Inch

TIR: 0.002 Inch (0.05 mm)

Balance: G2.5 per ISO 1940 and ANSI S2-19-75

Roll Finish: 4 Ra, 8 Ra, 16 Ra, 32 Ra

Roll Coatings: None, Black Hard Coat Anodize, Natural Hard Coat Anodize, PC915 Plasma Coated

Shaft Material: 303 Stainless Steel

Drilled & Tapped Shaft Ends: None, 1/4-20 UNC, 5/16-18 UNC, 3/8-16 UNC, 1/2-13 UNC, M8x1.25, M10x1.5, M12x1.75

Load Ratings:

Size 1: 12, 25, 50, 100, 150 lbs

(55, 110, 225, 450, 670 N)

Size 2: 25, 50, 100, 200, 400 lbs

(110, 225, 450, 900, 1800 N)

Overload Capacity:

Size 1: 880 lbs (3914 N)

Size 2: 3000 lbs (13300 N)

Deflection of Sensor Beam: .005 Inch (.127 mm), Max

Materials: 6061, 7075-T6 Aluminum; 303, 304 Stainless Steel; Black Oxide Alloy Steel

Connector Positions (Standard):

6:00, 12:00 (Adjustable 180°)

REFERENCE DOCUMENTS

LOAD CALCULATOR

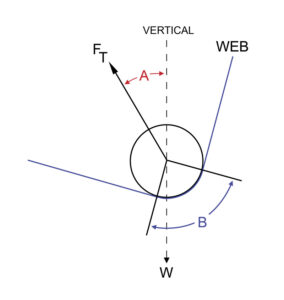

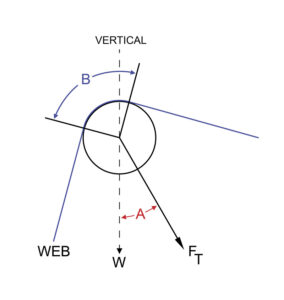

Force Above Horizontal

LOAD CALCULATOR

Force Below Horizontal

Consult data sheet matrix to estimate weight of roll shell and bearings.

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.