Blown Film Tension Control

Improve the quality and efficiency of blown film manufacturing with automatic tension control.

Tension Control for Blown Film Manufacturers

For businesses that are winding blown film, accurate tension measurement and control have proven to compensate for minor substrate imperfections and process deviations. In turn, this helps eliminate web and roll defects, especially when extensible materials are being wound.

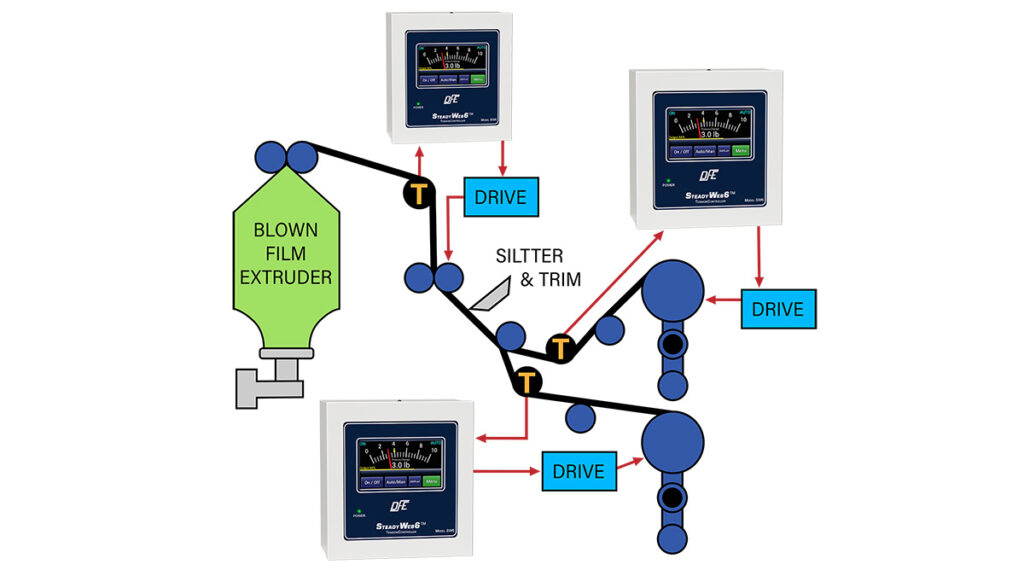

On a typical blown film line there are several points where tension transducers and electronics can be introduced for improved web management. Figure 1 illustrates the common placement of tension control within the production process. Starting at the blown film extruder, the bubble is collapsed at the top and flattened as the material is driven through the upper nip. This nip follows the extruder speed to maintain gauge control of the film substrate.

Starting at the blown film extruder, the bubble is collapsed at the top and flattened as the material is driven through the upper nip. This nip follows the extruder speed to maintain gauge control of the film substrate.

As the web exits the upper nip it passes over a roller equipped with load cells such as Model C Series Tension Transducers (paired with a live or dead shaft idler roll) or the Tension Roll® – a premium dead shaft idler with load cells integrated inside of the roll shell. The high-precision, tension sensing roll measures force on the web and outputs a proportionate signal to a SteadyWeb™ closed-loop tension controller.

The controller, in turn, outputs a compensation signal to the lower nip drive which is set to follow the upper nip speed. This control loop trims the web speed to keep tension constant.

Depending on the application, the web may pass through a slitter station after the lower nip (and/or trimmer), splitting the material off into two paths. Each web is then wound onto a core on it’s own turret winder. To ensure smooth, consistent roll build-up, tension control is added to each winder.

In the rewind zone, tension transducers are introduced in the web path just before the final idler roll. The measured tension signal is fed into each SteadyWeb™ tension controller. The tension controllers output a compensating voltage signal for each driven core on their respective winder. A percentage of taper-tension may also be configured and stored for each specific job to ensure progressive tension is properly delivered that meets roll handling and storage stability requirements.

In blown film extrusion, web tension is a variable that must be controlled to achieve consistent output and statistical process control. More and more, converters and manufacturers are being asked to provide documentation that verifies roll winding tension has been delivered within a predetermined spec or as part of a service level agreement.

Typical blown film tension control systems incorporate:

• A closed-loop tension controller such as the SteadyWeb™ 6

• A load cell such as the Tension Roll® Transducer

• A pneumatic or electric clutch, or a motor drive system

Customers integrating tension control with a PLC most often utilize:

• A load cell signal amplifier such as the TA1 TrueTension™ Amplifier

• A load cell such as the Tension Roll® Transducer, a pair of convertible load cells such as the Model C Series Transducers or Under Pillow Block Transducers such as the Model F Series

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.