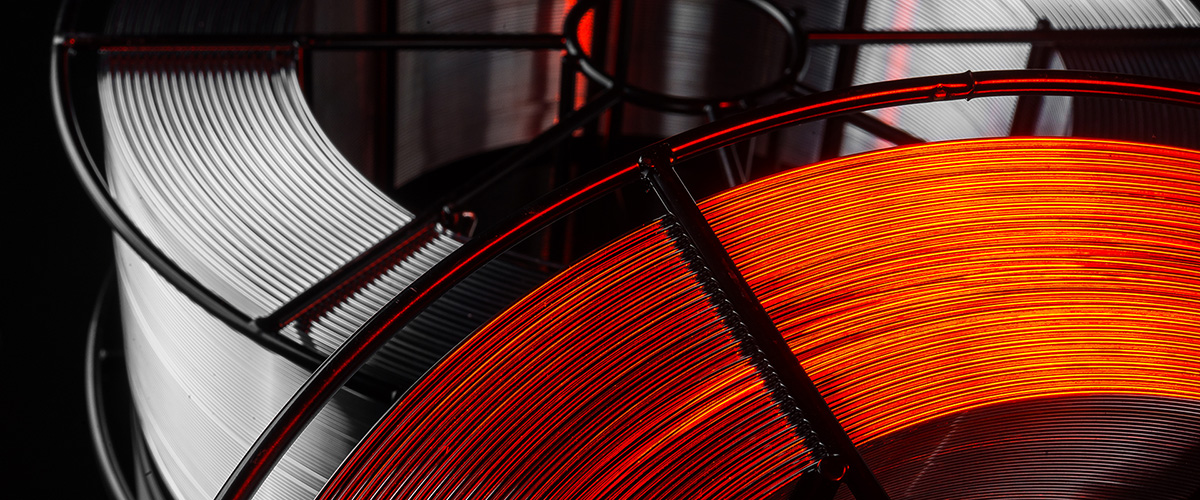

Wire and Cable Tension Control Solutions

Enhance wire and cable manufacturing with precision tension control systems designed for efficiency and quality.

WHY PRECISE TENSION CONTROL MATTERS IN WIRE AND CABLE MANUFACTURING

Consistent tension is the backbone of high-quality wire and cable production. At Dover Flexo Electronics (DFE), our advanced wire tension control and cable tension control systems empower manufacturers to achieve superior operational efficiency, repeatable product quality, and minimal downtime. Whether you’re drawing, extruding, annealing, stranding, insulating, jacketing, twisting, spooling, or coiling, our tension control systems deliver the precision needed to optimize every stage of production.

Our solutions help maintain uniform wire diameter, smooth surface finishes, and consistent insulation thickness, ensuring your products meet the highest industry standards. By reducing wire damage, tangling, and production errors, DFE’s tension control technology enhances productivity and profitability.

KEY APPLICATIONS OF TENSION CONTROL IN WIRE AND CABLE PRODUCTION

Our systems are engineered to support a wide range of wire and cable manufacturing processes:

Drawing, Extruding, and Annealing: Precise wire tension control ensures uniform wire diameter and a smooth surface finish, improving product consistency.

Stranding: Protect individual wires from damage with controlled tension, resulting in stronger, more reliable cables.

Insulation and Jacketing: Maintain uniform thickness around wires or cables for enhanced durability and performance.

Twisting: Ensure consistent twists and cable integrity with accurate cable tension control.

Spooling and Coiling: Prevent tangling and bunching, ensuring smooth unwinding and high-quality spools.

DFE’S ADVANCED TENSION CONTROL SOLUTIONS

DFE offers a family of high-performance load cells, including the Filament TriWheel™, Ribbon TriWheel™, LT, and VNW transducers, designed to measure and control wire tension from a few grams to hundreds of pounds or kilograms. These versatile load cells accommodate various form factors, making them ideal for diverse wire and cable applications.

When paired with our SteadyWeb™ 6 Digital Tension Controller, these load cells form a turn-key tension control system that is easy to commission and requires minimal training. This closed-loop solution ensures precise tension management, enabling manufacturers to optimize production with minimal investment.

BENEFITS OF DFE’S WIRE AND CABLE TENSION CONTROL SYSTEMS

Implementing DFE’s tension control solutions delivers measurable advantages:

Minimize Stretch and Breakage: Reduce wire damage during manufacturing for higher yield and quality.

Increase Production Speeds: Optimize processes to achieve faster manufacturing without compromising quality.

Reduce Tangling and Wrap-Up: Eliminate “bird nests” and ensure smooth spooling and coiling.

Expand Product Range: Produce a wider variety of products on a single machine with adaptable tension control.

Ensure Repeatable Performance: Achieve consistent results across production runs.

Deliver Higher Quality Products: Meet stringent industry standards with uniform, reliable cables.

Simplify Operations: Reduce reliance on specialized operators with user-friendly systems.

WHY CHOOSE DOVER FLEXO ELECTRONICS?

With decades of expertise in tension control technology, DFE is a trusted partner for wire and cable manufacturers worldwide. Our innovative solutions, including the TriWheel™, LT, VNW transducers, and SteadyWeb™ 6 controller, are designed to meet the unique challenges of modern manufacturing. By investing in DFE’s tension control systems, you can enhance efficiency, reduce costs, and deliver superior products to your customers.

Typical turn-key tension control solutions incorporate:

• A closed-loop tension controller such as the SteadyWeb™ 6 Digital Tension Controller

• A load cell such as the TriWheel™ Tension Load Cell, VNW Tension Transducer, Ribbon Filament Tension Transducer or Low Tension Transducer

• A Pneumatic Brake, Magnetic Particle Brake, Hysteresis Brake, Clutch or Motor Drive System

Customers integrating tension control with a PLC most often utilize:

• A load cell signal amplifier such as the TA1 TrueTension™ Amplifier

• A load cell such as the TriWheel™ Tension Load Cell, VNW Tension Transducer, Ribbon Filament Tension Transducer or Low Tension Transducer

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

RESOURCES

Application Note: Tension Control for Wire & Cable Manufacturing (PDF)