Tire Manufacturing Tension Control

Improve the quality and efficiency of tire manufacturing processes with automatic tension control.

Tension Control for Tire Producers

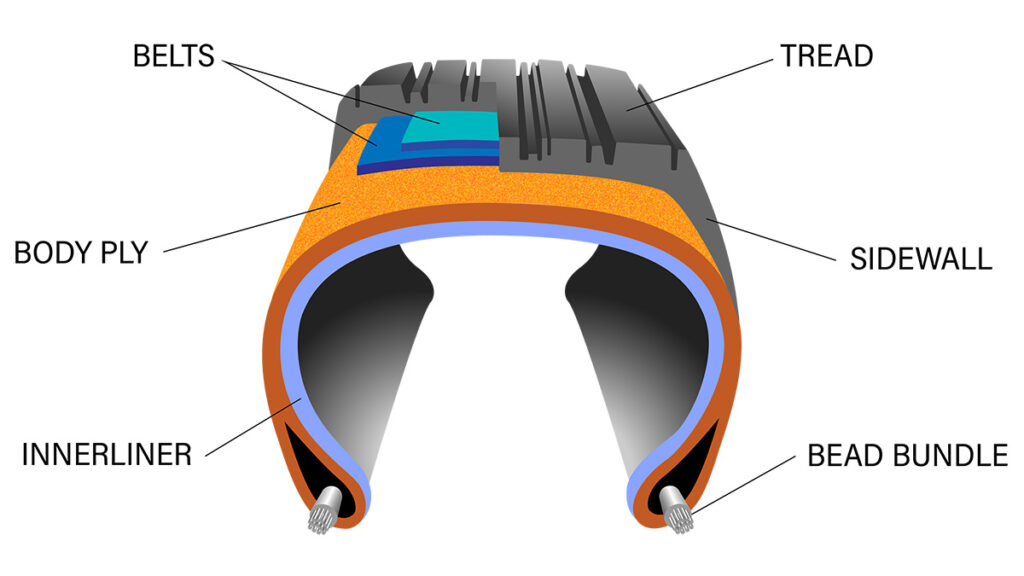

For tire manufacturers trying to achieve defect-free product, identifying and minimizing tension deviations throughout the tire manufacturing process is critical. Dover Flexo Electronics has, over the years, been successful in helping several large tire producers correct process problems that affect product quality. Here are some examples of tension measurement and control improvements made in three separate sub-processes at tire plants in the Southeast. Steel Tire Cord

Steel Tire Cord

Steel-braided cord used in manufacturing steel-belted radial tires is made up of 10 – 15 wires that are packaged together by a twister. Upon entering the twister the wires must match their running tension in order for the manufacture of high-quality steel cord to result.

Prior to the twister station, hold-back tension on each wire is created by a tensioning device which can be manually adjusted by the machine operator. Traditionally, at the start of a job run, the operator measures the tension on each wire with a hand-held tensiometer and adjusts the individual strand tension accordingly.

The problem with this method of tension measurement is that the lack of repeatability from wire to wire (and from run to run if different operators are performing the measuring and adjustments) will cause cord output quality to vary.

The solution at one plant was to install tension transducers to accurately and simultaneously measure all wire tensions throughout a run. This upgrade resulted in consistent finished cord quality from reel to reel. The new system incorporated 12 Ribbon-Filament Tension Transducers with tension indicators to monitor running tension continuously on each wire. Small manual adjustments to the tensioning device are still made by operators when deviations in wire tension are noted throughout the process.

The new system incorporated 12 Ribbon-Filament Tension Transducers with tension indicators to monitor running tension continuously on each wire. Small manual adjustments to the tensioning device are still made by operators when deviations in wire tension are noted throughout the process. Sidewall Material

Sidewall Material

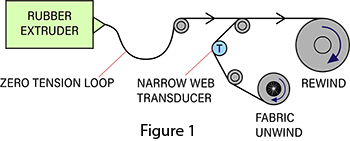

In another of the early tire-making subprocesses, latex impregnated rubber sidewall material is extruded and wound onto reels for further processing. The winding is performed at very low (almost zero) tension to avoid stretching the material. In its uncured state, the latex impregnated rubber is very tacky, so as it is wound onto its reel a fabric backing/liner is applied. This keeps each layer of rubber separated from the next. See figure 1.

Tension on the moving fabric liner, as it comes together with the rubber, should be controlled for two reasons:

If too little tension is applied during winding, the fabric tends to bunch, wrinkle or fold over as it is being taken up into the reel with the sidewall material. If too much tension is created, the fabric tends to dig into the soft rubber leaving a deep textured pattern.

When the full reels of sidewall material are later unwound downline and laid into the tire machine, indentations and impressions in the rubber can create hidden air pockets or surface deformation. Then, when the material layers are heated during the curing process, air pockets expand and the final result is likely to be a defective tire. To solve the problem, a pneumatic brake was used on the fabric liner unwind in conjunction with an automatic tension controller, and a 25 pound load-rated 14” Narrow Web Tension Transducer measuring 12 pounds of tension. With this system, the customer was able to successfully reduce the process waste level from approximately 25% to less than 1%.

To solve the problem, a pneumatic brake was used on the fabric liner unwind in conjunction with an automatic tension controller, and a 25 pound load-rated 14” Narrow Web Tension Transducer measuring 12 pounds of tension. With this system, the customer was able to successfully reduce the process waste level from approximately 25% to less than 1%. Steel Belt Assembly

Steel Belt Assembly

The same plant was experiencing problems on a line producing steel belt material for radial tires. The back-end of the process involves impregnating braided steel wire into soft, uncured rubber. At the start of the process the rubber web, which is softer and tackier than the side wall material, is wound on a core and has a peel-off fabric liner. As the rubber unwinds into a tire assembly machine, the fabric is pulled off and wound onto a separate take-up reel.

Problems in the process developed because the fabric adhered too strongly to the rubber. As the rubber was pulled into the tire assembly machine it was stretched in opposite directions, often resulting in web breakage. Accurate tension control on the fabric liner was again essential to solving the customer’s problem. In conjunction with edge guiding, the customer was able to reduce the waste on the bead material from approximately 20% to less than 1%. DFE’s web tension and filament control systems improved the tire producers’ bottom line by reducing scrap and allowing their process to run at higher speeds. The tension systems’ ROI was less than a month in each use case.

Typical tire manufacturing tension control solutions incorporate:

• A closed-loop tension controller such as the SteadyWeb™ 6

• A load cell such as the Tension Roll® Transducer, Narrow Web Transducer or Very Narrow Web Transducer

• A Pneumatic Brake, Magnetic Particle Brake, Clutch or Motor Drive System

Customers integrating tension control with a PLC most often utilize:

• A load cell signal amplifier such as the TA1 TrueTension™ Amplifier

• A load cell such as the Tension Roll® Transducer, a pair of convertible load cells such as the Model C Series Transducers or Under Pillow Block Transducers such as the Model F Series.

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.