Composite Manufacturing Tension Control

How tension control enhances composite manufacturing.

In the composite manufacturing industry, producing high-quality, lightweight, and durable components for aerospace, automotive, marine, and renewable energy applications requires precision at every stage. Materials such as prepregs, woven reinforcements (e.g., carbon fiber, glass fiber, aramid), adhesives, and vacuum bagging consumables are processed through complex methods like automated fiber placement (AFP), resin transfer molding (RTM), and lamination. A critical factor in ensuring the quality and consistency of these processes is precise tension control. Dover Flexo Electronics (DFE), a leader in tension control solutions since 1974, provides products that complement composite manufacturing by optimizing material handling, reducing defects, and improving efficiency. This article explores how DFE’s tension control systems enhance the use of composite materials, ensuring high-performance outcomes.

THE ROLE OF TENSION CONTROL IN COMPOSITE MANUFACTURING

Composite manufacturing involves processing materials in web, filament, or tow form, often under precise conditions to achieve desired mechanical properties. Prepregs, for instance, are fibers pre-impregnated with resin, requiring careful handling to maintain uniform resin content and fiber alignment. Woven reinforcements, such as carbon or glass fiber fabrics, demand consistent tension to prevent stretching or wrinkling during layup or lamination. Adhesives and vacuum bagging materials, like release films and peel plies, must be applied uniformly to ensure proper bonding and part release. In processes like AFP, RTM, or sandwich-structured composite lamination, improper tension can lead to defects such as wrinkles, air gaps, misalignment, or uneven resin distribution, compromising part quality.

DFE’s tension control products—including tension transducers (load cells), closed-loop controllers like the SteadyWeb 6™, and pneumatic or magnetic particle brakes—address these challenges by maintaining precise tension throughout the manufacturing process. These systems measure and adjust tension in real time, ensuring materials are processed consistently, reducing waste, and enhancing productivity. Below, we explore how DFE’s solutions complement key composite manufacturing processes and materials.

COMPLEMENTING PREPREGS AND WOVEN REINFORCEMENTS IN AUTOMATED FIBER PLACEMENT (AFP)

Automated Fiber Placement (AFP) is a cutting-edge process used to create complex composite structures, particularly in aerospace and wind energy. AFP involves robotic systems laying down prepreg tapes or fiber tows (e.g., carbon or glass fiber) onto molds or mandrels. Precise tension control is critical during the layup stage to ensure consistent deposition and prevent defects like tow buckling or gaps. DFE’s tension control systems, such as the Filament TriWheel™ , Ribbon TriWheel™ or VNW transducers, integrate with AFP creel house systems to manage the tension of multiple tows. These transducers use semiconductor strain gauge technology to deliver high-sensitivity measurements, enabling real-time adjustments via closed-loop controllers like the SteadyWeb™ 6.

For example, thermoset prepregs, which are tacky at room temperature, require heating to activate the resin for bonding. DFE’s systems ensure that tension remains stable as tows are fed from bobbins to the layup head, preventing stretching or slack that could disrupt resin flow or fiber alignment. In integrated bobbin designs, where the distance from bobbins to the layup head is short, DFE’s quick-response brakes (e.g., pneumatic or magnetic particle brakes) allow for rapid tension adjustments, ensuring precision for intricate geometries. By maintaining optimal tension, DFE’s products complement prepregs and reinforcements, resulting in stronger, defect-free composite parts.

ENHANCING SANDWICH-STRUCTURED COMPOSITE LAMINATION

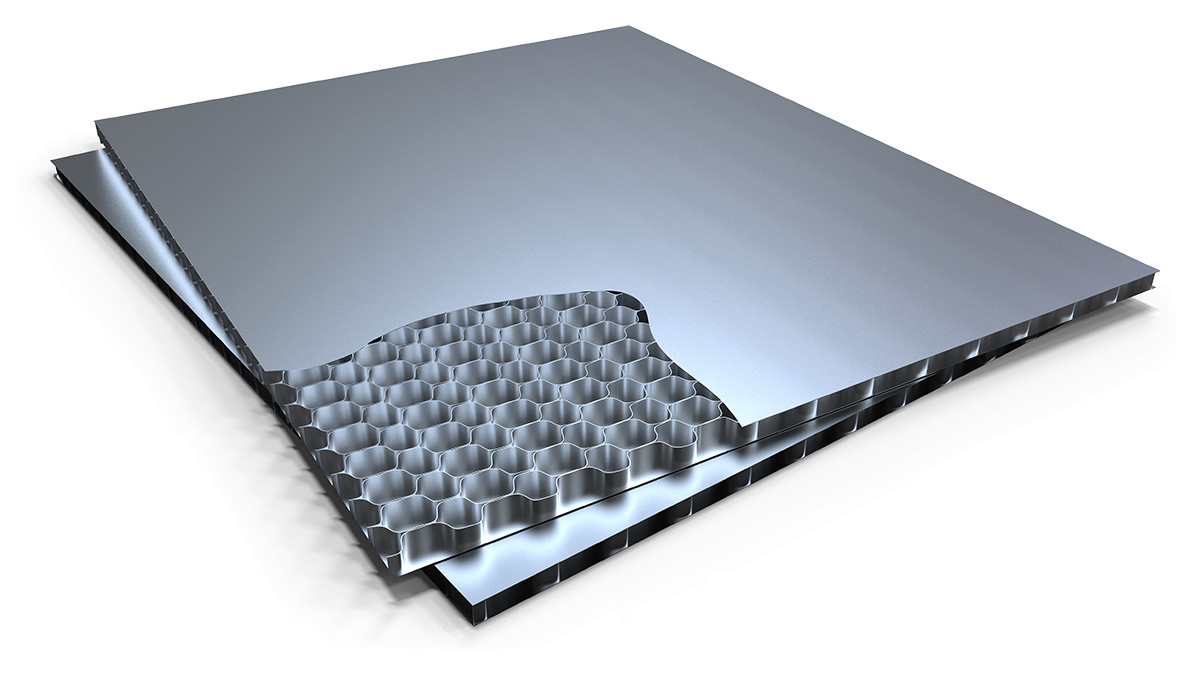

Sandwich-structured composites, widely used in aerospace and marine applications, consist of lightweight cores (e.g., honeycomb or foam) bonded between stiff skins (e.g., carbon fiber or fiberglass prepregs). The lamination process involves applying adhesives and skins under controlled conditions to achieve uniformity and strength. Tension control is vital to prevent slack webs or over-stretched materials, which can cause air gaps, wrinkles, or uneven bonding.

DFE’s tension control solutions, such as the Tension Roll® transducer, are ideal for lamination processes. The Tension Roll® combines a roll shell with dual tension sensors, providing accurate tension measurement across the web. Paired with a closed-loop controller, it ensures that materials like adhesive films and woven reinforcements are applied with consistent tension, reducing defects. For instance, during the application of epoxy film adhesives, precise tension prevents stretching, ensuring uniform adhesive thickness and strong bonds. Similarly, in honeycomb core shaping, DFE’s systems maintain tension on skin materials, enhancing shear and compression strength in the final panel. By optimizing material handling, DFE’s products complement the structural integrity of sandwich composites.

SUPPORTING VACUUM BAGGING AND CONSUMABLES

Vacuum bagging is a common technique in composite manufacturing, used to consolidate materials during curing in processes like RTM or autoclave curing. Consumables such as vacuum bagging films, release films, peel plies, and sealant tapes are applied over prepregs or reinforcements to create a sealed environment for resin infusion and curing. Proper tension during the application of these materials ensures smooth, wrinkle-free surfaces and effective resin flow.

DFE’s Model C transducers, known for their high-sensitivity semiconductor strain gauges, are well-suited for handling thin, flexible consumables. These transducers measure tension on narrow webs or films, preventing over-tension that could tear delicate materials or under-tension that could cause wrinkles. For example, when applying nylon peel plies or polyester release films, DFE’s closed-loop systems adjust tension dynamically, ensuring uniform contact with the composite layup. This complements the performance of vacuum bagging materials by improving part surface quality and easing demolding, reducing scrap and rework.

IMPROVING EFFICIENCY IN RESIN INFUSION AND ADHESIVE APPLICATION

Resin infusion processes, such as RTM, involve injecting resins (e.g., epoxy or polyester) into dry fiber reinforcements under vacuum. Adhesive application, such as core splice adhesives or epoxy syntactics, is also critical for bonding composite layers or filling gaps. Both processes require precise material handling to ensure uniform resin or adhesive distribution. DFE’s tension control systems enhance these processes by maintaining consistent tension on reinforcement fabrics or adhesive films as they are fed into molds or bonding stations.

For instance, in RTM, dry carbon or glass fiber fabrics must be positioned without stretching or wrinkling to ensure proper resin wet-out. DFE’s Narrow Web transducers, designed for narrow or low-tension applications, provide precise tension control, complementing the dimensional stability of woven reinforcements. Similarly, when applying adhesive films, DFE’s systems prevent stretching or misalignment, ensuring consistent bond strength. By reducing defects like resin-rich or resin-starved areas, DFE’s products enhance the reliability of resin infusion and adhesive bonding, critical for high-performance composites.

BENEFITS ACROSS THE COMPOSITE MANUFACTURING PROCESS

DFE’s tension control products offer several benefits that complement composite materials:

Reduced Waste: By preventing defects like wrinkles, tears, or misalignment, DFE’s systems minimize material waste, lowering costs for expensive materials like carbon fiber prepregs or aramid reinforcements.

Improved Quality: Consistent tension ensures uniform fiber alignment, resin distribution, and bonding, resulting in stronger, lighter, and more reliable composite parts.

Increased Productivity: Automated tension control reduces the need for manual adjustments, allowing processes to run at higher speeds with minimal downtime.

Versatility: DFE’s transducers and controllers are adaptable to various materials and processes, from low-tension consumables to high-tension reinforcements, making them suitable for diverse applications.

CONCLUSION

In composite manufacturing, where precision is paramount, DFE’s tension control products play a vital role in complementing materials like prepregs, woven reinforcements, adhesives, and vacuum bagging consumables. By ensuring consistent tension in processes like AFP, lamination, vacuum bagging, and resin infusion, DFE’s solutions enhance material performance, reduce defects, and boost efficiency. With over 50 years of expertise, DFE’s tension transducers, controllers, and brakes provide reliable, high-performance solutions that meet the rigorous demands of modern composite manufacturing. As the industry evolves, integrating advanced tension control remains essential for producing high-quality composites that push the boundaries of engineering innovation.

A typical DFE tension control solution includes a closed-loop controller (e.g., SteadyWeb™ 6), a load cell (e.g., Tension Roll® or Model C transducer), and a brake or motor drive system. These components work together to deliver precise, repeatable tension, complementing the unique properties of composite materials.

For manufacturers integrating with PLCs, DFE offers tension amplifiers with analog or ethernet, such as the TA1 and TA500, enabling seamless data collection and process monitoring.

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

RESOURCES

Composite Manufacturing Tension Control (PDF)