The Benefits Of Tension Control In Sandwich-Structured Composites Manufacturing

Improve quality and reduce waste in composites manufacturing with precise, automatic tension control.

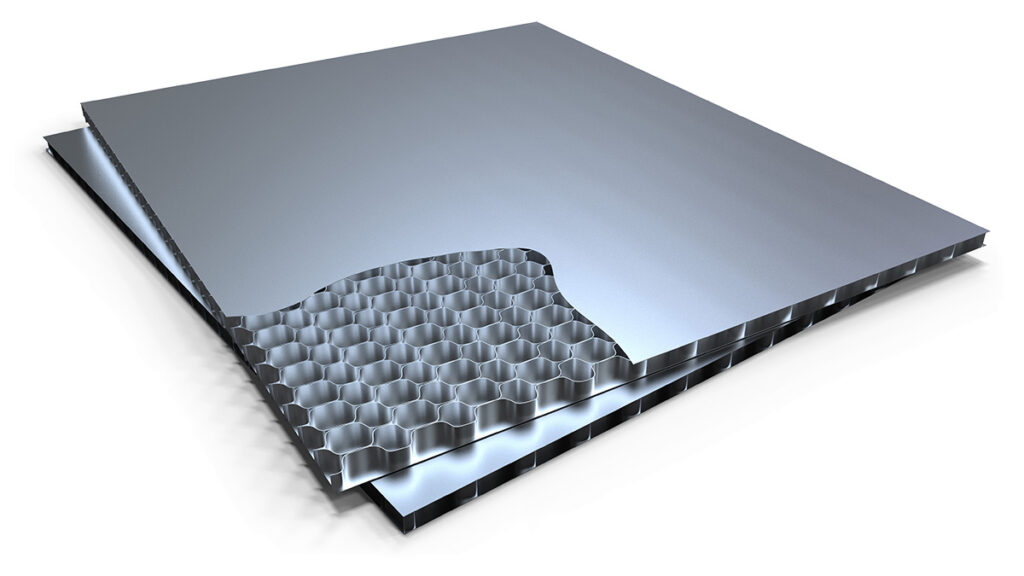

Sandwich-structured composites, widely used in aerospace, marine, automotive, and construction industries, combine lightweight cores (e.g., honeycomb, foam, balsa wood) with stiff, high-strength skins (e.g., carbon fiber, glass fiber, or metal) to create components with exceptional strength-to-weight and stiffness-to-weight ratios. Manufacturing these composites involves complex processes such as polymer extrusion, honeycomb shaping, adhesive coating, resin infusion, and lamination, each requiring precise material handling to ensure quality. Tension control is a critical factor in achieving uniformity, reducing defects, and optimizing performance. Dover Flexo Electronics (DFE), with over 50 years of expertise in tension control solutions, provides advanced systems that enhance the production of sandwich-structured composites. This article explores how DFE’s tension control technology complements composite manufacturing, improving quality, efficiency, and sustainability.

THE IMPORTANCE OF TENSION CONTROL IN SANDWICH-STRUCTURED COMPOSITES

Sandwich composites are engineered to balance lightweight cores with robust skins, often bonded using adhesives or resins. The core, typically made of materials like Nomex® or aluminum honeycomb, polymeric foams (e.g., polyurethane, PMI), or balsa wood, provides shear resistance and spacing, while the skins, made of fiber-reinforced polymers (e.g., carbon or glass fiber prepregs) or metals, handle bending and in-plane loads. Manufacturing processes like lamination, resin transfer molding (RTM), vacuum bagging, and automated layup require precise tension to ensure proper material alignment, bonding, and curing. Without consistent tension, issues such as slack webs, over-stretched materials, wrinkles, air gaps, or uneven resin distribution can occur, compromising the composite’s structural integrity.

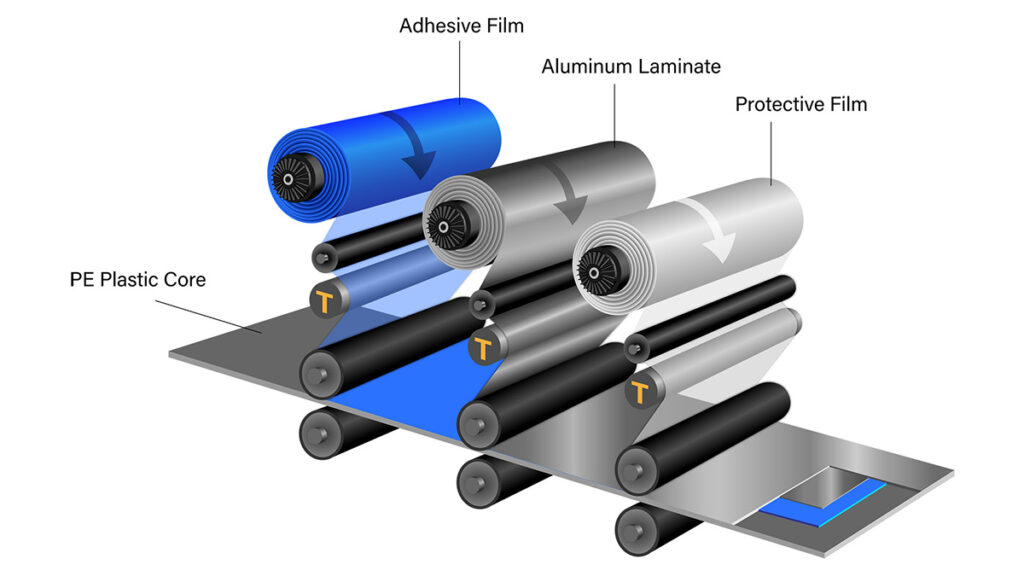

For example, in lamination, applying skins to cores involves feeding prepreg fabrics or adhesive films through rollers or presses. Uneven tension can lead to air entrapment or misalignment, reducing adhesion and causing delamination under load. Similarly, in honeycomb shaping, maintaining balanced tension on skins prevents curling or warping, ensuring the panel’s ability to distribute shear and compression forces effectively. DFE’s tension control systems, including transducers, controllers, and brakes, address these challenges by delivering real-time tension measurement and adjustment, ensuring high-quality composites with minimal waste.

TENSION CONTROL IN KEY MANUFACTURING PROCESSES

Lamination Processes: Lamination is a cornerstone of sandwich composite manufacturing, where skins and cores are bonded under pressure and heat, often using epoxy or polyester adhesives. Tension control is vital to prevent defects that affect adhesion and structural performance. Slack webs can cause wrinkles, reducing the panel’s ability to transfer shear forces, while over-tension can stretch materials, leading to uneven thickness or fiber misalignment. DFE’s Tension Roll® transducer, a roll shell with dual tension sensors, provides accurate tension measurement across the web, ensuring uniform application of materials like carbon fiber prepregs or adhesive films. Paired with the SteadyWeb™ 6 closed-loop controller, it dynamically adjusts tension to maintain consistency, even at high line speeds.

In aerospace applications, where sandwich panels with Nomex® honeycomb cores and carbon fiber skins are common, DFE’s systems ensure precise tension during lamination, enhancing flexural strength and reducing scrap. For instance, maintaining consistent tension on thin glass fiber skins prevents stretching, ensuring uniform bonding with PMI foam cores, which is critical for lightweight aircraft interiors.

Honeycomb Shaping and Core Processing: Honeycomb core shaping involves expanding or forming materials like aluminum or Nomex® into hexagonal cells, which are then bonded to skins. Tension control is essential when applying skins to these cores, as uneven tension can cause curling or structural imbalances. DFE’s Model C transducers, equipped with high-sensitivity semiconductor strain gauges, are ideal for low-tension applications, such as handling delicate honeycomb materials or thin adhesive films. These transducers integrate with pneumatic brakes or motor drives to adjust tension rapidly, ensuring smooth core-skin interfaces.

In marine applications, where balsa wood cores are paired with fiberglass skins, DFE’s systems maintain tension during core shaping and skin application, preventing warping and ensuring panels meet high impact resistance standards for boat hulls. This precision complements the dimensional stability of core materials, enhancing the composite’s overall performance.

Resin Infusion and Vacuum Bagging: Resin infusion processes, such as RTM, and vacuum bagging are used to consolidate sandwich composites, often involving dry fiber reinforcements, resins, and consumables like peel plies or release films. Precise tension ensures that materials like woven carbon fiber fabrics or vacuum bagging films are applied without wrinkles, promoting uniform resin flow and curing. DFE’s Narrow Web transducers are designed for narrow or low-tension materials, providing accurate measurements for consumables like polyester peel plies. These systems prevent over-tension that could tear films or under-tension that could disrupt resin distribution, complementing the performance of infusion resins and reinforcements.

For example, in wind turbine blade manufacturing, where large sandwich panels with foam cores and glass fiber skins are common, DFE’s tension control ensures uniform application of vacuum bagging materials, reducing resin-rich areas and improving fatigue resistance. This synergy enhances the reliability of large-scale composite structures.

Automated Layup and 3D Printing: Modern composite manufacturing increasingly incorporates automation, such as automated tape laying (ATL) or 3D printing of sandwich structures with continuous fiber reinforcements. In ATL, prepreg tapes are laid onto cores or molds, requiring precise tension to prevent tow buckling or gaps. DFE’s Filament TriWheel transducers, designed for filamentary materials, integrate with ATL creel systems to manage tension across multiple tows, ensuring accurate placement. In 3D printing, where meta-sandwich structures with lattice or foam cores are emerging, DFE’s systems control tension on continuous carbon fiber filaments, enhancing mechanical properties like stiffness and energy absorption.

For instance, in automotive applications, 3D-printed sandwich panels with PLA cores and carbon fiber skins benefit from DFE’s tension control, which ensures consistent fiber tension during printing, improving compressive strength and crashworthiness. This complements the flexibility of additive manufacturing, enabling customized, lightweight components.

AUTOMATION AND INDUSTRY 4.0

As composite manufacturing embraces Industry 4.0, DFE’s tension control systems offer seamless integration with automated production lines and data-driven processes. The TA500 EtherNet/IP™ and EtherCAT® amplifiers enable connectivity with PLCs, allowing real-time tension data to be monitored and analyzed alongside other process parameters. This integration supports predictive maintenance, quality control, and process optimization, reducing downtime and enhancing traceability. For example, in aerospace autoclave processing, where sandwich composites undergo high-pressure curing, DFE’s systems provide tension data that correlates with resin flow and curing metrics, ensuring compliance with stringent standards like AS9100.

SUSTAINABILITY AND COST EFFICIENCY

Tension control also contributes to sustainability in composite manufacturing. By minimizing defects like wrinkles or delamination, DFE’s systems reduce material waste, particularly for costly materials like carbon fiber prepregs or aramid honeycombs. Precise tension enables faster production speeds, lowering energy consumption in processes like autoclave curing or resin infusion. Additionally, DFE’s durable transducers, such as the Tension Roll® with a 10x overload protection rating, offer long service life, reducing replacement costs and environmental impact. In construction applications, where recyclable sandwich panels with kraft honeycomb cores are gaining traction, DFE’s systems optimize material usage, supporting eco-friendly manufacturing practices.

STAND-ALONE TENSION CONTROL SOLUTIONS

DFE’s turn-key solutions are tailored to the unique demands of sandwich composite manufacturing, offering versatility across unwind, rewind, and process zones. A typical system includes:

Closed-Loop Tension Controller: The SteadyWeb™ 6 provides precise, automated tension adjustments, supporting high-speed production with a user-friendly interface.

Load Cell: The Tension Roll® Transducer or Model C Transducer delivers accurate tension measurements for webs, filaments, or consumables, with high-sensitivity strain gauges for low-tension applications.

Brake or Drive System: Pneumatic brakes, magnetic particle brakes, or motor drives ensure rapid tension response, accommodating materials from delicate films to robust reinforcements.

These components work together to maintain consistent tension, complementing the properties of cores, skins, adhesives, and consumables. For example, in a marine lamination line, the Tension Roll® measures tension on fiberglass skins, the SteadyWeb™ 6 adjusts brake force, and pneumatic brakes respond instantly, ensuring defect-free panels.

TENSION SOLUTIONS FOR PLC INTEGRATION

Load Cell Signal Amplifier: Models such as the TA1 TrueTension™ Amplifier or TA500 EtherNet/IP™ Tension Amplifier.

Load Cell: Models such as the Tension Roll® Transducer, a pair of convertible load cells such as the Model C Series Transducers or Under Pillow Block Transducers such as the Model F Series.

CONCLUSION

Tension control is a cornerstone of high-quality sandwich-structured composite manufacturing, enabling precise handling of cores, skins, adhesives, and consumables across diverse processes. DFE’s advanced tension control solutions, including transducers, controllers, and brakes, enhance material performance, reduce defects, and improve efficiency in applications from aerospace panels to wind turbine blades. By integrating with automated systems and supporting sustainable practices, DFE’s technology meets the evolving demands of modern composite manufacturing. Contact a DFE application engineer today to discuss how our solutions can optimize your specific tension control requirements, ensuring superior composite parts that meet the rigorous standards of today’s industries.

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

RESOURCES

Tension Control for Sandwich-Structured Composites Applications (PDF)