Tension Control in Cast and Blown Film Extrusion and Winding

Film extrusion processes—cast and blown—differ fundamentally in geometry, cooling, and film properties. These differences dictate how tension must be controlled during winding. Improper tension control leads to defects such as telescoping, starring, and wrinkles, which compromise downstream converting and customer satisfaction. This paper explores the mechanical and control implications of each process and offers best practices for achieving stable rolls, with a strong emphasis on load cell feedback control for blown film and the role of speed-follow adjustments in intermediate zones.

INTRODUCTION

Tension control is the single most important variable in winding. It governs strain, which in turn determines roll hardness, flatness, and stability. While cast and blown films share the same end goal—a wound roll—they arrive at the winder with very different histories. Understanding these differences is key to designing and operating tension control systems that prevent defects and optimize productivity.

PROCESS OVERVIEW

Cast Film

• Extruded through a flat die and quenched on a chill roll.

• Rapid cooling yields uniform gauge and low orientation.

• High clarity and dimensional stability.

• Typically wound at high speeds (up to 1,000 m/min).

Blown Film

• Extruded through a circular die and inflated into a bubble.

• Cooling is gradual; gauge variation and bubble instability are common.

• Film exhibits biaxial orientation and residual stresses.

• Winding speeds are moderate (100–300 m/min).

Mechanical Behavior

• Gauge Variation: Cast film is nearly perfect; blown film is not.

• Orientation: Blown film has significant machine and transverse direction orientation, making it sensitive to strain.

• Residual Stress: Blown film retains stresses from bubble collapse, which can relax during winding.

Winding Dynamics

Roll structure depends on tension history. Too much tension and you get starring; too little and you get telescoping. Cast film’s high speed magnifies any control error. Blown film’s variability demands flexibility in control—but without overstretching, which can distort orientation and cause wrinkles.

TENSION CONTROL STRATEGIES

Cast Film

Goal: Maintain uniform tension at high speed.

Challenges: High-speed winding requires responsive control systems. Thin gauges are sensitive to tension spikes.

Best Practices: Use closed-loop tension control with load cells. Minimize tension zones—short spans reduce variability. Avoid tension spikes during acceleration/deceleration.

Blown Film

Goal: Compensate for gauge and width variations without overstretching, while maintaining stable winding tension.

Load cell feedback control provides direct, real-time measurement of web tension, enabling precise closed-loop control. Unlike dancers, which introduce mechanical compliance and lag, load cells offer faster response and higher accuracy—critical for handling the cyclic tension changes caused by bubble instability and gauge variation.

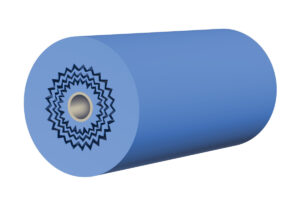

Best Practices for Load Cell Systems: Ensure proper calibration and alignment of load cells. Using a built-to-order product such as the DFE Tension Roll® simplifies the installation and alignment process. Use PID tuning optimized for the dynamic nature of blown film. Integrate with torque-controlled drives for smooth tension transitions, except in intermediate tension zones. Monitor feedback loops continuously—small errors can accumulate into roll defects.

INTERMEDIATE TENSION ZONES

Not all zones are created equal. Between major sections—such as the collapsing frame and the winder in blown film, or between chill rolls and the winder in cast film—you often have intermediate tension zones. These zones are not accumulating material; they are simply transporting the web.

Why Speed-Follow Control?

Torque control works well for winders and unwinders where diameter changes, but in intermediate zones with fixed-diameter rolls, torque control can cause tension drift. Instead, speed-follow control is preferred:

- The intermediate drive is slaved to the master speed reference (usually the winder or extruder).

- A small trim signal from a load cell fine-tunes the speed to maintain tension.

- This approach avoids hunting and instability common with torque control in fixed-diameter zones.

Best Practice: Use speed-follow as the primary control. Add load cell feedback trim for fine correction. Keep torque control for zones where diameter changes.

CONTROL TECHNOLOGIES

Closed-Loop with Load Cells

This is the gold standard for both cast and blown film winding today. It provides direct tension measurement and immediate correction, outperforming dancer-based systems in accuracy and responsiveness.

Torque Control + Load Cell Feedback

Essential for winders/unwinders where diameter changes.

Speed-Follow + Trim

Ideal for intermediate zones to maintain stability and avoid tension drift.

TROUBLESHOOTING COMMON DEFECTS

Telescoping

Usually caused by too little tension or poor roll alignment. The roll shifts sideways because the layers are not locked in place. Starring

Starring

Excessive tension or winding too hard creates radial cracks in the roll. Often seen in stiff films or when taper tension is misapplied. Wrinkles

Wrinkles

Uneven tension or poor web handling upstream. Can also occur if taper tension is too aggressive, reducing tension too quickly near the end of the roll.

Cyclic Baggy Defects in Blown Film

Often caused by poor PID tuning or sensor drift in the load cell feedback loop. These defects repeat with bubble instability cycles.

Slippage in Wound Rolls

Layers sliding against each other, leading to offset edges or core crush. Most common in:

- Slick Films: Highly polished cast films, metallized films, and low surface energy films (BOPP, CPP).

- Thin Gauges: Lower friction and higher tendency to slip under pressure.

- High-Speed Winding: Centrifugal forces exacerbate slippage.

- Low Tension Settings: Insufficient nip pressure to lock layers together.

Prevention Tips: Increase winding tension slightly (within safe strain limits). Use a winding nip or lay-on roll to add pressure. Consider surface treatment or anti-slip coatings if slippage is chronic. Avoid excessive roll hardness—hard rolls can promote slippage by reducing interlayer friction.

Taper Tension Issues

Taper tension is the practice of gradually reducing winding tension as roll diameter increases. It’s essential for preventing starring and core crush in stiff films. Where It Applies:

- Thicker or Stiffer Films: These build internal stresses quickly as the roll grows.

- High-Modulus Materials: PET, nylon, and heavy laminates benefit from taper tension.

- Not for Slick Films: Reducing tension too much on slick films can cause slippage. In these cases, taper tension should be minimal or omitted.

Best Practice: Start with full tension at the core. Reduce tension gradually (typically 10–50%) as diameter increases. Tune taper based on film modulus and slippage risk.

BEST PRACTICES, SUMMARIZED

• For cast film: Invest in high-speed responsive controls and maintain tight calibration.

• For blown film: Focus on load cell feedback systems and proper tuning.

• For intermediate zones: Use speed-follow with trim, not torque.

• Always verify feedback loops and sensor health.

• Train operators on tension sensitivity—small changes matter.

CONCLUSION

While both cast and blown films ultimately need to be wound into stable rolls, their tension control requirements are fundamentally different because of how they are made and what mechanical properties they carry into the winder. Cast film is a high-speed process with excellent gauge uniformity and low orientation. That means tension control is primarily about precision at speed. The challenge is not variability—it’s responsiveness. Blown film is slower but far more variable. Bubble instability, gauge variation, and residual stresses make tension control a balancing act. Both processes benefit from speed-follow control in intermediate zones, with load cell trim for fine correction. Torque control belongs on winders and unwinders where diameter changes—not on fixed-diameter rolls. In the quest to ensure quality and efficiency, the investment in proper control systems and operator training pays for itself many times over.

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

RESOURCES

Tech Bulletin: Tension Control in Cast and Blown Film Extrusion and Winding (PDF)