Company Milestones and Timeline

Our Journey from Garage Start-Up to Market Leader.

In a Garage in Somersworth, NH.

The new unwind and rewind controllers were much easier to install and service than products offered by the competition.

The company principals take serious steps to solidify their business venture.

After the purchase of his partner's shares.

The P3 was smaller than the RTC/UTC controllers and utilized an advanced aircraft-grade servo control valve.

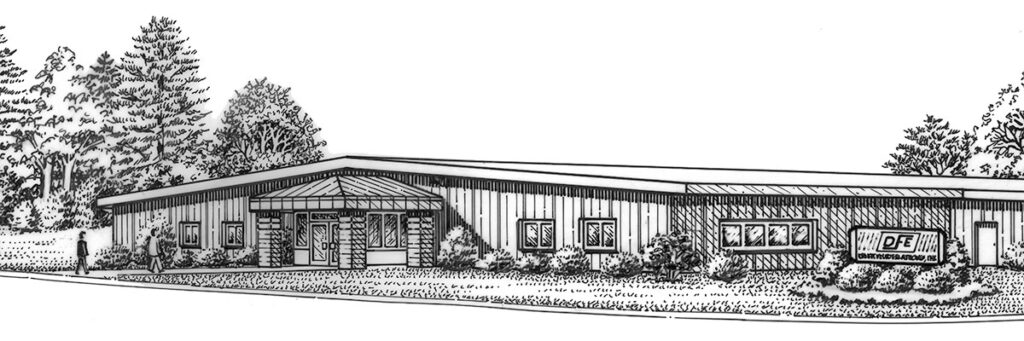

The company moves to its present location in Rochester, NH, expanding office and manufacturing space by 300%.

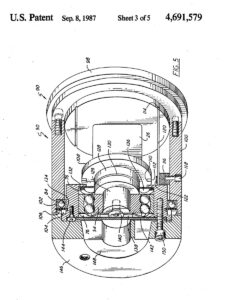

The Model U Series "Universal" Transducer is born. This cartridge-type load cell could be configured into a variety of different form factors.

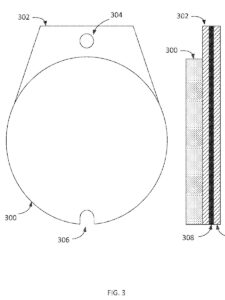

Features of this tension transducer are recognized as novel, resulting in the issuance of US Patent# 4691579.

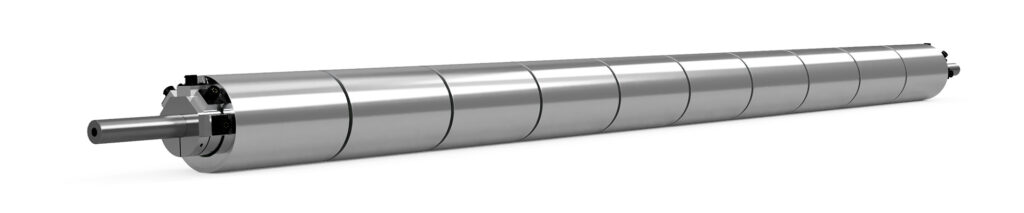

The Tension Roll® Transducer integrated a dead shaft idler roll and tension sensors into one easy-to-install system. The Narrow Web Transducer is a cantilevered version of this model.

These tension transducers are recognized as the first integrated load cell rollers and issued US Patent# 4784004, European Patent# EP0304226A1.

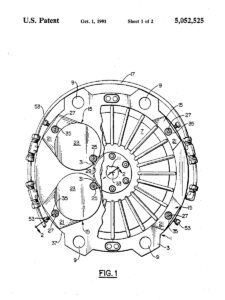

DFE begins manufacturing a full line of pneumatic tension brakes covering a wide HP and torque range. The brakes feature convenient tool-less quick change pads.

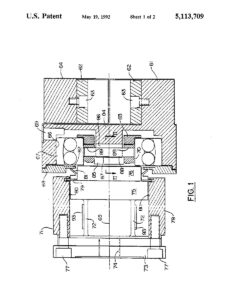

This cartridge-type load cell replaces the previous Model U and Model DS transducers, featuring a convertible live and dead shaft configurations.

The quick-release torque post design of DFE's pneumatic brakes, providing tool-less pad changes, is awarded US Patent# 5052525.

This load cell, recognized for it's convertible coupling design, was awarded US Patent# 5113709.

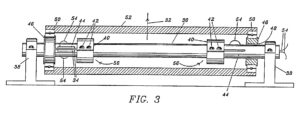

The Model STR was a more sophisticated version of the Tension Roll®, incorporating multiple tension-sensing rollers onto a single shaft assembly.

The first device capable of use in all three tension zones: Unwind, intermediate, and rewind. It was a big hit with thousands sold.

It was our first digital controller, and according to AI search, may have been the world’s-first digital tension controller. It featured a knob for scrolling up and down instead of buttons, as well as recipe storage for quick recall of job parameters.

The building expansion doubles the size of the company, while also creating a test facility for product development and training.

A compact, analog tension controller suitable for use in all tension zones.

A compact, modular tension controller with advanced features such as digital calibration, job storage & recall and taper tension.

These third generation tension amplifiers introduced Quik-Cal™ digital calibration. Digital calibration eliminates the instability associated with worn or corroded adjustment pots, increasing reliability.

An advanced modular tension controller with color LCD display. The SteadyWeb 5™ could be used in all tension zones and was compatible with a wide range of torque devices.

The pads are 99% effective at suppressing brake squeal.

A lower-cost, open-loop controller with diameter compensation for less demanding tension applications.

An amplifier that limits energy sent to tension transducers in a manufacturing area, reducing the risk of fire or explosion.

In total, over 86,000 tension load cells are sold by DFE's 40th year of operation.

Recognized for the product's effectiveness at reducing tension brake squeal, is awarded US Patent# 9321605.

This tension indicator with color touchscreen display simultaneously displays left, right and total web tension. A great tool for detecting and preventing baggy edges or web steering problems.

This controller features an easy-to-use menu system and touch interface.

A compact, inexpensive tension load cell amplifier with built-in diagnostics and Quik-Cal™ pushbutton calibration.

Kenneth Ekola sells DFE to Glenn & Cindy St. Peter. Glenn performed numerous roles for the company during his career, including engineer, sales manager and field service.

The TA500-EIP tension amplifier features built-in diagnostics, Quik-Cal™ digital push-button calibration, 0-10 VDC, 4-20 ma and EtherNet/IP™ connectivity.

This stackable filament tension transducer has configurable wheel positions to accommodate different applications or tension ranges.

We could not have arrived here without the competency and loyalty of our employees, and the stewardship of our leadership team.

This variant of the TA500 amplifier features EtherCAT® protocol, providing the fastest ever interconnect speed between DFE load cells and Ethernet fieldbus.

This stackable ribbon tension transducer has configurable wheel positions to accommodate different applications or tension ranges. Rollers are available to process narrow web material from 1 to 4 inches wide.

RAPID DELIVERY

QUALITY ASSURANCE

RESPONSIVE TECH SUPPORT