Model F Series Tension Load Cell / Tension Transducer

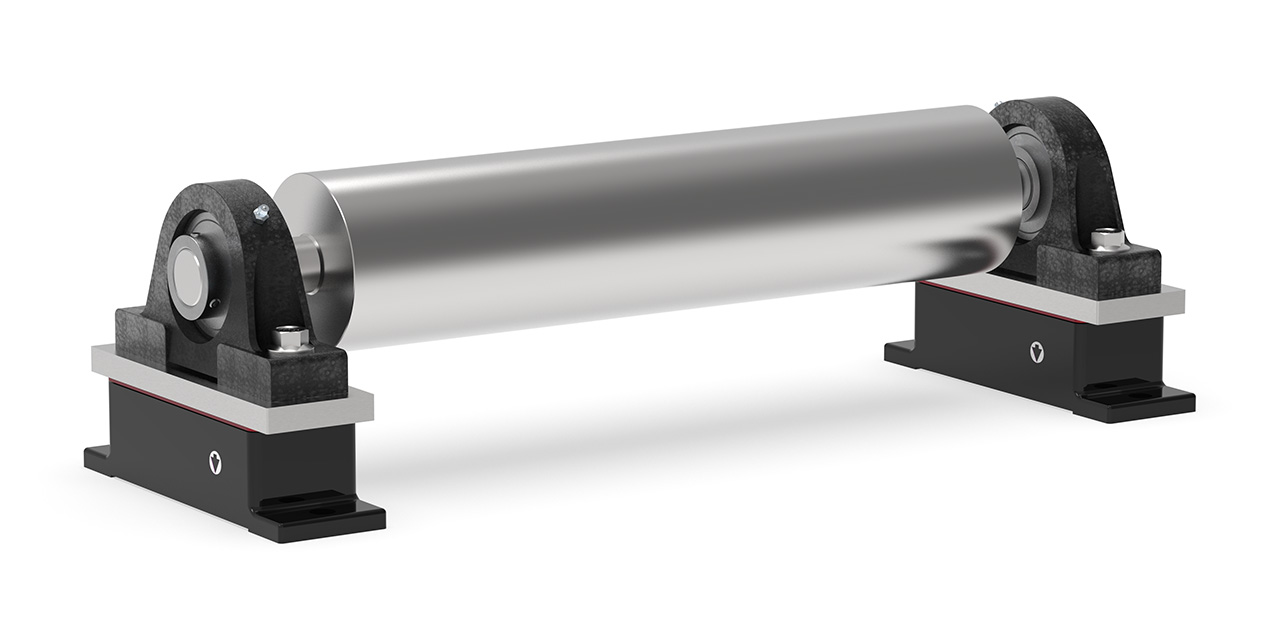

The Model F is heavy-duty tension load cell used with pillow-block bearings to accurately measure web, wire or cable tension in applications that use live shaft idler rolls or pulleys.

Model F Series tension load cells mount under pillow-block bearings at each end of an idler roll shaft. Designed for use in demanding tension measurement environments, the Model F tension transducer’s shell has a one-piece aluminum base with a removable stainless steel top plate. A rubber seal between the base and top plate prevents water ingress and dust contamination to IP65 standards. The tension sensor’s electrical connector is located at the end of a short cable for simpler access during installation.

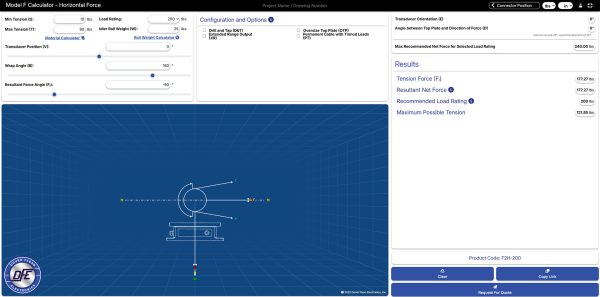

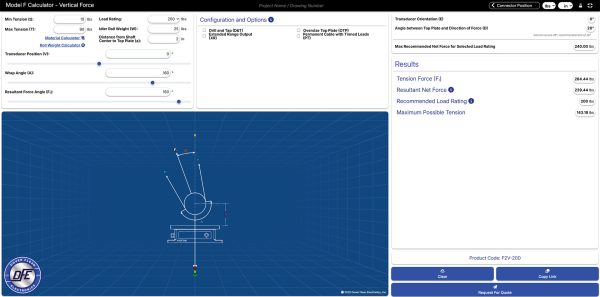

The Model F is available in a V (vertical) configuration for use when the applied force is roughly perpendicular to the top plate of the load cell. It is also available in an H (horizontal) configuration for use when the applied force is closer to parallel to the load cell top plate.

The Model F is available in two sizes – 2 and 3, and mounts on a flat surface using one bolt (size 2) or two bolts (size 3) on each end. Load ratings range from 100 to 1200 lbs in the size 2 and 1000 to 7500 lbs in the size 3 (7500 lb load rating in H configuration only).

FEATURES

• 5 year tension-free warranty

• Highly accurate and reliable semiconductor strain gauge technology

• Corrosion-resistant stainless steel and aluminum construction

• Attached cable with amphenol connector

• Tethered top plate safety feature prevents separation from transducer in the unlikely event of beam breakage

• Robust overload protection – load stops limit beam deflection to 125% of rated output

• Designed to meet CE mark requirements for Measurement & Control equipment: EN61326 for EMI

• Designed to meet the IP65 standard for ingress protection

BENEFITS

• Low-maintenance design

• Entire length of top plate is clear for pillow-block installation

• Can be installed in any orientation

• Mechanical stop provides protection from overloads

• Splash resistant

• Use with live-shaft or dead-shaft idler rolls

OPTIONS

• Drill and Tap (D&T) – Drill and tap the top plate

• Extended Range output (XR) – Produces twice the output signal for a given load rating

• Oversized Top Plate (OTP) – For mounting of oversized pillow-block bearing

• Permanently Attached Cable with Tinned Leads (PT) – Replaces standard pigtail cable connector with flying leads

Do you have more questions about this product?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

ELECTRICAL

Excitation: 5 VDC Max (Std), 10 VDC Max (XR Option)

Output: 50 mV/V, Nominal

Strain Gauge Resistance: 100 Ohms, Nominal

Circuit Configuration (Pair): Full Wheatstone Bridge

Non-Repeatability: ±1/4% Full Span (FS)

Combined Non-Linearity & Hysteresis:

±1/2% Full Span (FS)

Temperature Range: -10°F to 200°F (-23°C to 93°C)

Temperature Coefficient:

.02% FS per °F, Typical (.036% FS per °C)

Mating Electrical Connector (Mil-Spec) P/N:

721-1445

Connector Pin Assignment:

A = Signal Output

B = Excitation (+)

C = Excitation (-)

MECHANICAL

Load Ratings:

Size 2: 100, 200, 400, 800, 1200 lbs (450, 900, 1800, 3600, 5350 N)

Size 3: 1000, 2500, 5000, 7500 lb (4450, 11125, 22250, 33360 N)

Static Overload Capacity:

5X Load Rating, Minimum

Materials: 6061, 7075-T6 Aluminum; 303, 304 Stainless Steel; Black Oxide Alloy Steel

Weight: Size 2: 7 lbs (3 Kg)

Size 3: 42 lbs (19 Kg)

REFERENCE DOCUMENTS

Click the preferred product in the table below, then select CAD format to download.

Complete the form to enable your file download

| Product Code | Size | Force Direction | Load Rating | Top Plate | ||

| F2V-100 | 2 | Vertical | 100 lbs (445 N) / pair | Standard | ||

| F2V-200 | 2 | Vertical | 200 lbs (890 N) / pair | Standard | ||

| F2V-400 | 2 | Vertical | 400 lbs (1779 N) / pair | Standard | ||

| F2V-800 | 2 | Vertical | 800 lbs (3559 N) / pair | Standard | ||

| F2V-1200 | 2 | Vertical | 1200 lbs (5350 N) / pair | Standard | ||

| F2V-100-OTP | 2 | Vertical | 100 lbs (445 N) / pair | Oversized | ||

| F2V-200-OTP | 2 | Vertical | 200 lbs (890 N) / pair | Oversized | ||

| F2V-400-OTP | 2 | Vertical | 400 lbs (1779 N) / pair | Oversized | ||

| F2V-800-OTP | 2 | Vertical | 800 lbs (3559 N) / pair | Oversized | ||

| F2V-1200-OTP | 2 | Vertical | 1200 lbs (5350 N) / pair | Oversized | ||

| F3V-1000 | 3 | Vertical | 1000 lbs (4450 N) / pair | Standard | ||

| F3V-2500 | 3 | Vertical | 2500 lbs (11125 N) / pair | Standard | ||

| F3V-5000 | 3 | Vertical | 5000 lbs (22250 N) / pair | Standard | ||

| F3V-1000-OTP | 3 | Vertical | 1000 lbs (4450 N) / pair | Oversized | ||

| F3V-2500-OTP | 3 | Vertical | 2500 lbs (11125 N) / pair | Oversized | ||

| F3V-5000-OTP | 3 | Vertical | 5000 lbs (22250 N) / pair | Oversized | ||

| F2H-100 | 2 | Horizontal | 100 lbs (445 N) / pair | Standard | ||

| F2H-200 | 2 | Horizontal | 200 lbs (890 N) / pair | Standard | ||

| F2H-400 | 2 | Horizontal | 400 lbs (1779 N) / pair | Standard | ||

| F2H-800 | 2 | Horizontal | 800 lbs (3559 N) / pair | Standard | ||

| F2H-1200 | 2 | Horizontal | 1200 lbs (5350 N) / pair | Standard | ||

| F2H-100-OTP | 2 | Horizontal | 100 lbs (445 N) / pair | Oversized | ||

| F2H-200-OTP | 2 | Horizontal | 200 lbs (890 N) / pair | Oversized | ||

| F2H-400-OTP | 2 | Horizontal | 400 lbs (1779 N) / pair | Oversized | ||

| F2H-800-OTP | 2 | Horizontal | 800 lbs (3559 N) / pair | Oversized | ||

| F2H-1200-OTP | 2 | Horizontal | 1200 lbs (5350 N) / pair | Oversized | ||

| F3H-1000 | 3 | Horizontal | 1000 lbs (4450 N) / pair | Standard | ||

| F3H-2500 | 3 | Horizontal | 2500 lbs (11125 N) / pair | Standard | ||

| F3H-5000 | 3 | Horizontal | 5000 lbs (22250 N) / pair | Standard | ||

| F3H-10000 | 3 | Horizontal | 10000 lbs (44500 N) / pair | Standard | ||

| F3H-1000-OTP | 3 | Horizontal | 1000 lbs (4450 N) / pair | Oversized | ||

| F3H-2500-OTP | 3 | Horizontal | 2500 lbs (11125 N) / pair | Oversized | ||

| F3H-5000-OTP | 3 | Horizontal | 5000 lbs (22250 N) / pair | Oversized | ||

| F3H-10000-OTP | 3 | Horizontal | 10000 lbs (44500 N) / pair | Oversized | ||

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.