The History of the Tension Roll® Transducer

The load cell roller that forever changed the printing and web converting industry.

At the time of it’s founding in 1974, Dover Flexo Electronics (DFE) was predominately a manufacturer of tension display and control equipment. By the 1980s, the company had established a solid reputation for equipment quality and reliability. In an effort to expand it’s product offering and more closely integrate components, DFE began to design load cells specific to web tension measurement applications.

At the time of it’s founding in 1974, Dover Flexo Electronics (DFE) was predominately a manufacturer of tension display and control equipment. By the 1980s, the company had established a solid reputation for equipment quality and reliability. In an effort to expand it’s product offering and more closely integrate components, DFE began to design load cells specific to web tension measurement applications.

DFE’s first cartridge-style load cells were released in the mid-80s. While in common use, shaft-end mounted load cells of the time shared many of the same inconveniences that still exist today. Factors such as cumbersome alignment and play adjustment (a coupling design feature that eliminates drift caused by shaft thermal expansion or deflection) could sometimes contribute to a frustrating installation experience. Additionally, the use of idler rolls that were not balanced properly or sized correctly, could lead to measurement instability or even premature load cell failure.

As a way to combat some of these drawbacks and inefficiencies, DFE’s founder, Ken Ekola, envisioned a load cell system that could be integrated within the roller itself. If successfully achieved, installation could become as simple as sliding the roll assembly into position and bolting down the shaft. Misalignment or substandard rolls would no longer be a factor contributing to measurement instability or drift. By using the thru-shaft as a load-stop, higher overload capabilities could also be achieved without any resulting damage to the sensing beams.

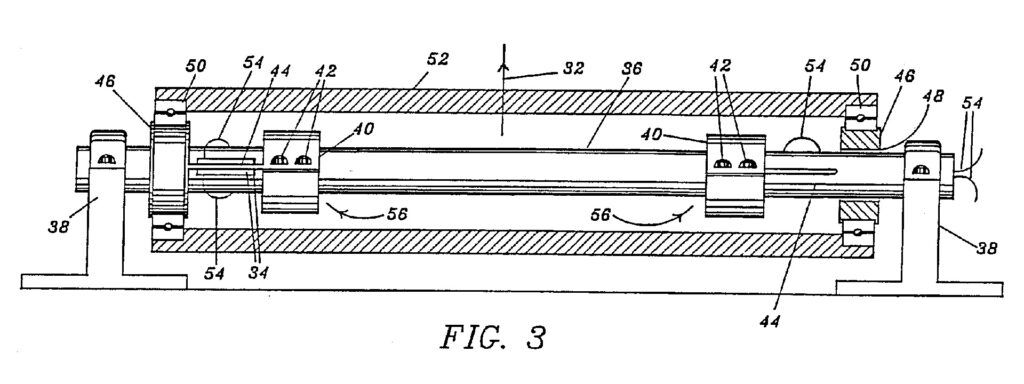

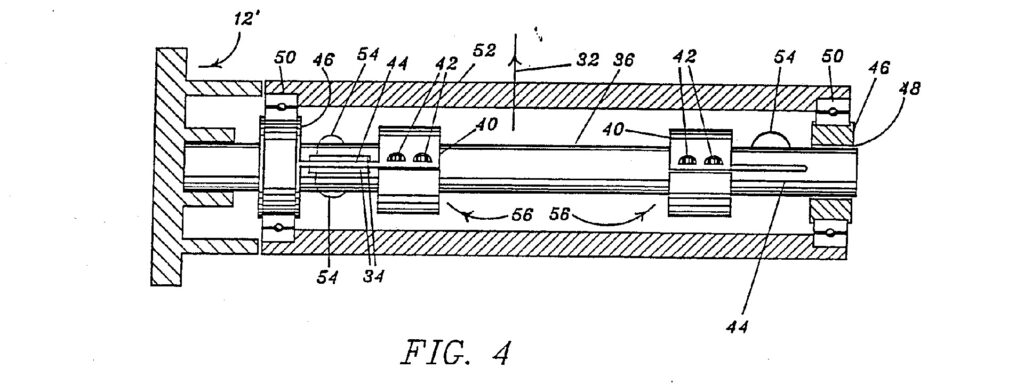

After a period of experimentation and refinement, a final design was submitted for patent protection in 1987. In 1988 patent# 4784004 was issued and published – the Tension Roll® had officially arrived.

A patent drawing for DFE’s original Tension Roll® design

As word spread, orders began to roll in. Customers from a variety of industries including paper, film, foil, printing and web converting were curious to see if the new design could live up to the hype.

In the immediate years to follow, thousands of Tension Roll® and Narrow Web (cantilevered version) transducers were manufactured for customers all over the world. If order volume is the best measuring stick used to define success, it seemed the marketplace had embraced the new roller for the convenience and performance advantages it was designed to deliver. Customer feedback from producers reinforced that they enjoyed the simple turn-key approach to retrofits, while OEM machine-builders appreciated the high-performance and customization options.

The original Tension Roll® design featured a continuous thru-shaft, precision-balanced roll shell and twin, single-plane sensing beams with 360 degree overload protection. Improvements to this design continued to progress through the 90s and 2000s. One revision was to reorient the single plane sensing-beam design to an over-and-under, twin-plane structure, delivering additional measurement stability and overload protection. Longer rollers would receive self-aligning bearings, helping to relieve uneven shear stresses across the sensing beams caused by increased shaft deflection at higher loads.

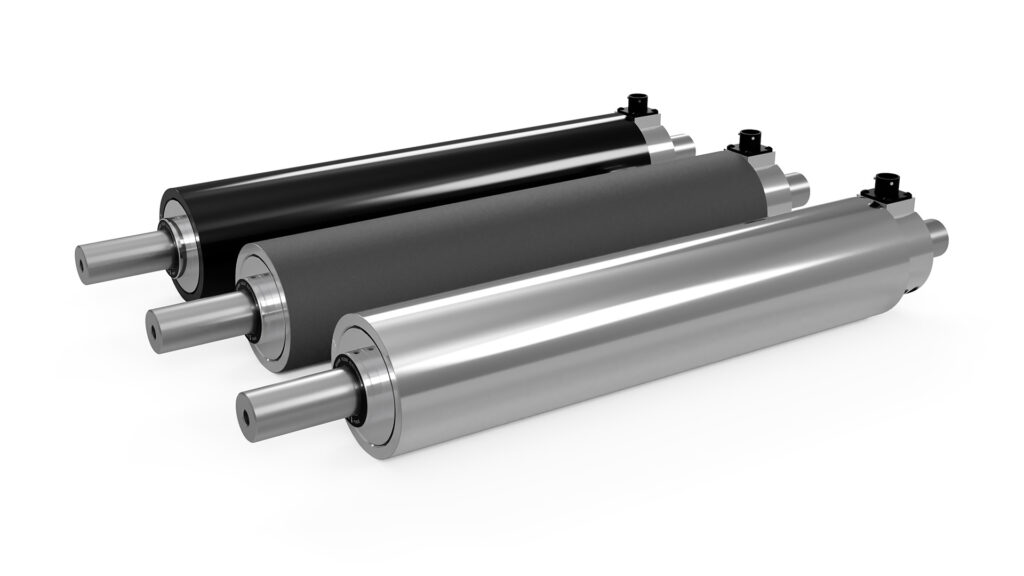

The cantilevered design now known as the Narrow Web Transducer

Today’s Tension Roll® carries forward the same robust performance and sensitivity as its predecessors. Constructed primarily of aluminum and stainless steel, the Tension Roll® is resistant to corrosion and highly durable. Roll shells are balanced to G2.5 standards and can be specified from 2.25 to 6 inches in diameter and in lengths up to 120 inches. Load ratings are available from 12 to 400 lbs (55 – 1,800N) with an overload capacity up to 3,000 lbs. Hard coat anodized, plasma coating and other custom roll finishes are also available. For wet and caustic operating environments, an all stainless steel version can be specified. The Tension Roll® is manufactured in the USA and backed by an industry-leading 5 year warranty.

Note of Interest: The Tension Roll® Transducer is also referred to by some of our customers as the Dover Roller, the Tension Roller and sometimes the Tension Measurement Roller. Any way you like it, this is the easiest way for printers and manufacturers to measure web tension on a press, converting line or coating line.

Do you need a Tension Roll® transducer with multiple transducer segments across the roll face? DFE makes a custom Tension Roll®, called a Segmented Tension Roll® transducer that measures web tension at multiple positions across the roll face at increments you specify. Find out more here.

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.