Ribbon Tri-Wheel™ Tension Load Cell

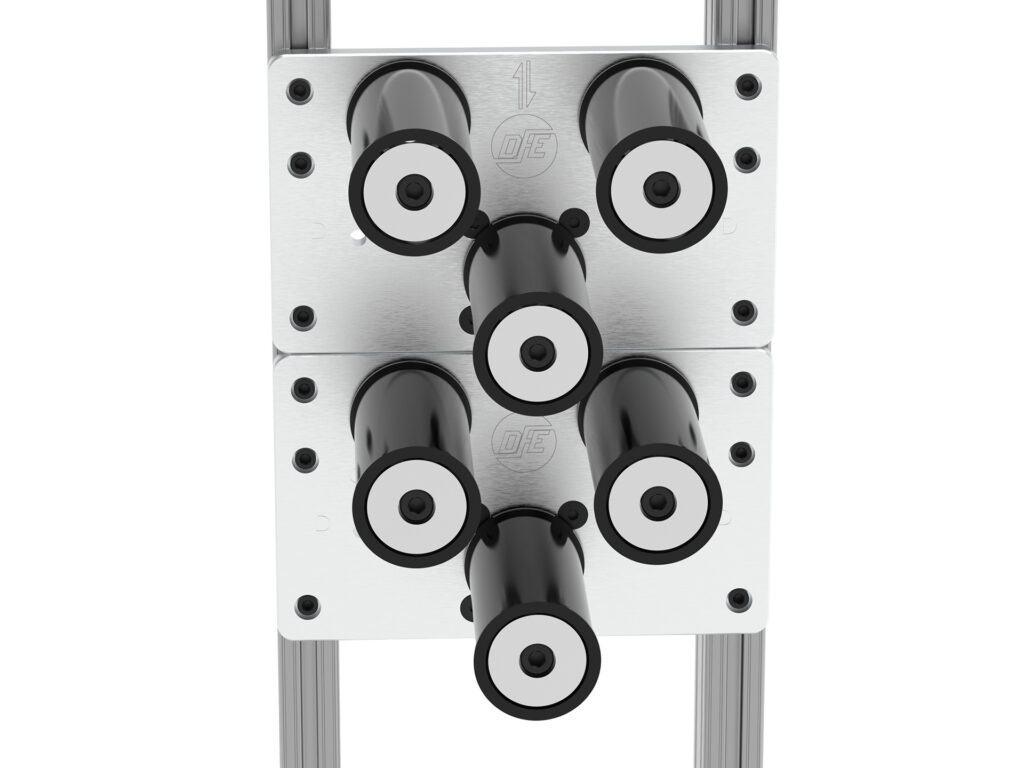

A modular, configurable load cell fixture designed to measure the tension of ribbon and narrow web materials.

The Tri-Wheel™ Tension Load Cell is a modular fixture designed to be installed individually or stacked in an array. The system incorporates a set of wheels with configurable positions, allowing an operator to select from multiple wrap angles. The minimum wrap angle position can be helpful when working with high tension applications or rigid materials with bend limitations. The maximum wrap angle narrows the measurement range of the load cell to deliver the highest possible accuracy, resolution and traction for the selected load rating.

The heart of the Tri-Wheel™ system is a high-performance semiconductor strain gauge load cell providing up to 33 times more signal output than similar foil gauge systems. The Tri-Wheel™ fixture incorporates hardcoat anodized aluminum wheels able to withstand wear from many common web substrates. Designed with quick integration in mind, the Tri-Wheel™ system is compatible with DFE amplifiers, indicators and controllers featuring Quik-Cal™ technology for rapid, reliable calibration.

Tri-Wheel Tension Load Cell with 4-Inch Ribbon Wheels

(Amplifiers Not Included)

HOW IT WORKS

Tension is measured by strain gauges embedded on a dual cantilevered beam and connected in a full Wheatstone bridge configuration. As the filament passes over the rotating wheel assembly coupled to the end of the transducer, the beam deflects slightly in response to tension. This produces a voltage signal proportional to tension. The output signal can be displayed as actual tension with a tension indicator or input to a closed-loop tension controller to modulate a torque device and maintain a precise tension set point.

FEATURES

• 5 year tension-free warranty

• Highly accurate and reliable semiconductor strain gage technology

• Stackable form-factor

• Wear-resistant hardcoat anodized aluminum wheels from 1 to 4 inches in width

• Load ratings available from 10 – 200 lbs (45 – 890N) for a wide operating range

• Configurable wrap angles for a wide selection of tension ranges and material paths

BENEFITS

• Accurate tension measurement of ribbon and narrow web materials

• Improve product quality and consistency in any narrow web process

• Reduced material waste

• Higher production with less downtime

Do you have more questions about this product?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

ELECTRICAL

Excitation: 5 VDC Max

Output: 100 mV/V, Nominal

Strain Gages: Semiconductor, 100 Ohms, nominal

Circuit Configuration: Full Wheatstone Bridge

Non-Repeatability: ±1/4% Full Span (FS)

Combined Non-Linearity & Hysteresis:

±1/2% Full Span (FS)

Temperature Range: -10°F to 200°F (-23°C to 93°C)

Temperature Coefficient:

.02% FS per °F, Typical (.036% FS per °C)

Mating Electrical Connector (Mil-Spec) P/N:

106-0050

Connector Pin Assignment:

A = Signal Output (-) D = Signal Output (+)

B = Excitation (+) E = Excitation (-)

C = Excitation (-) F = Excitation (+)

MECHANICAL

Overload Capacity: 1200lbs (5338N)

Deflection of Sensor Beam: 0.005 in. max (0.127mm)

Materials: Aluminum; Stainless Steel; Carbon Steel

Load Ratings: 10, 25, 50, 100, 200 lbs

(44, 111, 222, 445, 890 N)

Wheel Weight:

1-Inch Wide Ribbon Wheel: 0.45 lbs (204 g)

2-Inch Wide Ribbon Wheel: 0.56 lbs (255 g)

3-Inch Wide Ribbon Wheel: 0.66 lbs (299 g)

4-Inch Wide Ribbon Wheel: 0.75 lbs (341 g)

| TENSION RANGE FOR SELECTED WRAP ANGLE AND LOAD RATING | |||||

| Wrap Angle | 10 lbs | 25 lbs | 50 lbs | 100 lbs | 200 lbs |

| 15° | 0 – 19 lbs | 0 – 48 lbs | 0 – 96 lbs | 0 – 192 lbs | 0 – 384 lbs |

| 30° | 0 – 9.6 lbs | 0 – 24 lbs | 0 – 49 lbs | 0 – 99 lbs | 0 – 199 lbs |

| 60° | 0 – 5 lbs | 0 – 12.5 lbs | 0 – 25 lbs | 0 – 50 lbs | 0 – 100 lbs |

| 110° | 0 – 3.1 lbs | 0 – 7.6 lbs | 0 – 15.2 lbs | 0 – 30.4 lbs | 0 – 61 lbs |

| 180° | 0 – 2.5 lbs | 0 – 6.2 lbs | 0 – 12.5 lbs | 0 – 25 lbs | 0 – 50 lbs |

REFERENCE DOCUMENTS

Click the preferred product in the table below, then select CAD format to download.

Complete the form to enable your file download

| Product Code | Wheel Width | Load Rating | Wrap Angle | Connector Position |

| TW-1RW-10L-180DEG-12C | 1 Inch | 10 lbs (45 N) | 180 Degrees | 12:00 |

| TW-1RW-25L-180DEG-12C | 1 Inch | 25 lbs (111 N) | 180 Degrees | 12:00 |

| TW-1RW-50L-180DEG-12C | 1 Inch | 50 lbs (222 N) | 180 Degrees | 12:00 |

| TW-1RW-100L-180DEG-12C | 1 Inch | 100 lbs (445 N) | 180 Degrees | 12:00 |

| TW-1RW-200L-180DEG-12C | 1 Inch | 200 lbs (890 N) | 180 Degrees | 12:00 |

| TW-2RW-10L-180DEG-12C | 2 Inch | 10 lbs (45 N) | 180 Degrees | 12:00 |

| TW-2RW-25L-180DEG-12C | 2 Inch | 25 lbs (111 N) | 180 Degrees | 12:00 |

| TW-2RW-50L-180DEG-12C | 2 Inch | 50 lbs (222 N) | 180 Degrees | 12:00 |

| TW-2RW-100L-180DEG-12C | 2 Inch | 100 lbs (445 N) | 180 Degrees | 12:00 |

| TW-2RW-200L-180DEG-12C | 2 Inch | 200 lbs (890 N) | 180 Degrees | 12:00 |

| TW-3RW-10L-180DEG-12C | 3 Inch | 10 lbs (45 N) | 180 Degrees | 12:00 |

| TW-3RW-25L-180DEG-12C | 3 Inch | 25 lbs (111 N) | 180 Degrees | 12:00 |

| TW-3RW-50L-180DEG-12C | 3 Inch | 50 lbs (222 N) | 180 Degrees | 12:00 |

| TW-3RW-100L-180DEG-12C | 3 Inch | 100 lbs (445 N) | 180 Degrees | 12:00 |

| TW-3RW-200L-180DEG-12C | 3 Inch | 200 lbs (890 N) | 180 Degrees | 12:00 |

| TW-4RW-10L-180DEG-12C | 4 Inch | 10 lbs (45 N) | 180 Degrees | 12:00 |

| TW-4RW-25L-180DEG-12C | 4 Inch | 25 lbs (111 N) | 180 Degrees | 12:00 |

| TW-4RW-50L-180DEG-12C | 4 Inch | 50 lbs (222 N) | 180 Degrees | 12:00 |

| TW-4RW-100L-180DEG-12C | 4 Inch | 100 lbs (445 N) | 180 Degrees | 12:00 |

| TW-4RW-200L-180DEG-12C | 4 Inch | 200 lbs (890 N) | 180 Degrees | 12:00 |

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.