Better Web Process Control Through Tension Sensing

Inadequate tension control is the #1 cause of material processing mishaps. Reduce or eliminate winding defects and web breakages with a properly designed web tension control system.

WHY IS TENSION CONTROL IMPORTANT?

Inadequate tension control is the #1 cause of material processing mishaps. Solving tension-related problems unlocks both performance and quality benefits.

INCREASE SPEED AND PROCESS EFFICIENCY

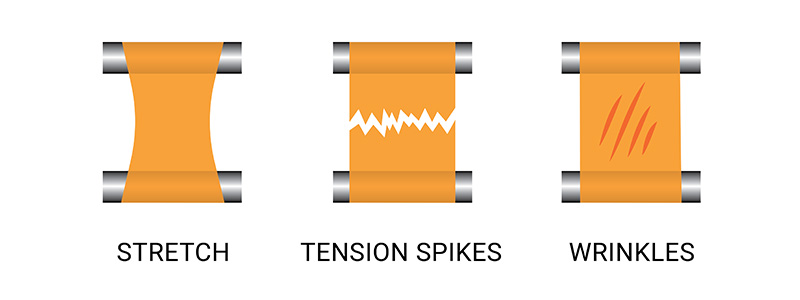

Eliminate material stretch, wrinkles, tension spikes and registration problems, allowing for increased speed and quality control.

REDUCE OR ELIMINATE WINDING DEFECTS

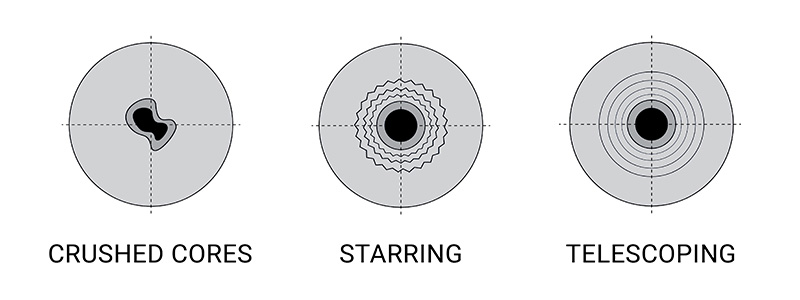

Web breakages, crushed cores, starring or telescoping can lead to higher scrap and labor costs. Most tension-related issues can quickly be resolved with a closed-loop controller. DFE tension controllers store up to 32 job profiles, enabling rapid recall of the settings optimized for each of your production runs.

EQUIPMENT THAT ENDURES, FOR THE BEST ROI

DFE tension control products are designed and manufactured in the USA and backed by an industry-leading 5 year warranty. Under typical operating conditions, DFE load cells and controllers often last 15-20 years or more.

SIMPLE TO USE & MAINTENANCE FREE

DFE controllers are designed to be operated with minimal training and configuration. Touchscreen interfaces can be programmed in 60 seconds or less by answering a few, simple on-screen menu prompts.

All DFE amplifiers feature Quik-CalTM digital push-button zero & calibration. Simply press to Zero the system, then hang the calibration weight and press Cal to lock it in.

![]()

The silicon strain gauge technology and dual cantilever design in all DFE load cells is the secret to their long life and high performance. DFE load cells are also designed to be maintenance-free. If failures occur outside of warranty coverage, repair services are available to extend equipment life further1.

SYSTEMS ENGINEERED FOR YOUR APPLICATION

DFE applications engineers have extensive experience assisting controls engineers and mechanical designers to develop tension systems suited for a wide range of materials and processes. Their primary goal is to help you get the most out of your technology investment by developing solutions that scale properly to fit all of your needs.

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.