Rotary Die Cutting Tension Control

Improve the performance of rotary die cutting machinery with precise, automatic tension control.

ACHIEVING PRECISION AND EFFICIENCY IN ROTARY DIE CUTTING

Rotary die cutting is a cornerstone of modern manufacturing, serving industries as diverse as packaging, automotive, medical, electronics, textiles, aerospace, and label printing. This versatile process transforms raw materials into precise components at scale, but its success hinges on a critical factor: Tension Control. In web-fed rotary die-cutting operations, maintaining consistent material tension is essential to unlocking peak performance, minimizing waste, and ensuring high-quality outcomes.

SEEMLESS MATERIAL FEED WITH CLOSED LOOP SYSTEMS

At the heart of effective tension management are closed-loop tension control systems. These advanced setups use real-time feedback—often from load cells—to maintain steady tension on the material as it feeds into the rotary die cutter. This ensures a smooth, uniform flow, drastically reducing the risk of jams, wrap-ups, or misfeeds. Such disruptions not only cause costly downtime but also generate unnecessary waste. By stabilizing the web, closed-loop systems keep production running efficiently, allowing manufacturers to focus on output rather than troubleshooting.

PRECISION THAT ELEVATES QUALITY

Accurate tension control does more than keep the process moving—it directly enhances the precision of every cut. With load cell feedback fine-tuning the tension, materials experience minimal stretching, tearing, or distortion during processing. The result is a finished product with consistent shape, size, and quality, meeting the exacting standards of industries like medical device manufacturing, electronics, labels and packaging. This reduction in defects translates to less scrap, optimizing material use and driving down costs—an advantage that’s both economical and sustainable.

PROTECTING EQUIPMENT, EXTENDING LIFESPAN

The benefits of tension control extend beyond the material to the machinery itself. A consistent, even feed reduces strain on critical components such as rolls, gears, bearings, motors, brakes, and cutting dies. Without the excessive wear caused by tension fluctuations, equipment maintains proper registration and die synchronization over time. This holistic approach not only minimizes maintenance headaches but also extends machine longevity, offering a significant return on investment for manufacturers.

THE ULTIMATE GOAL: PRODUCTIVITY AND EFFICIENCY

Across all rotary die-cutting applications, the objectives remain the same: maximize productivity while minimizing waste. Precise tension control is the linchpin that ties these goals together, delivering reliability and consistency in web material processing. Whether cutting intricate labels or robust automotive parts, a well-regulated tension system ensures that every run meets its potential—fewer interruptions, higher throughput, and a better bottom line.

DFE: LEADING THE WAY IN TENSION SOLUTIONS

Achieving these outcomes requires tools you can trust. DFE’s industry-leading tension-sensing transducers and controllers are engineered for precision and durability, empowering manufacturers to maintain optimal tension in even the most demanding applications. With a focus on quality and innovation, DFE solutions help businesses achieve the consistency and reliability needed to stay competitive in today’s fast-paced industries.

Typical tension control solutions incorporate:

• A closed-loop tension controller such as the SteadyWeb™ 6

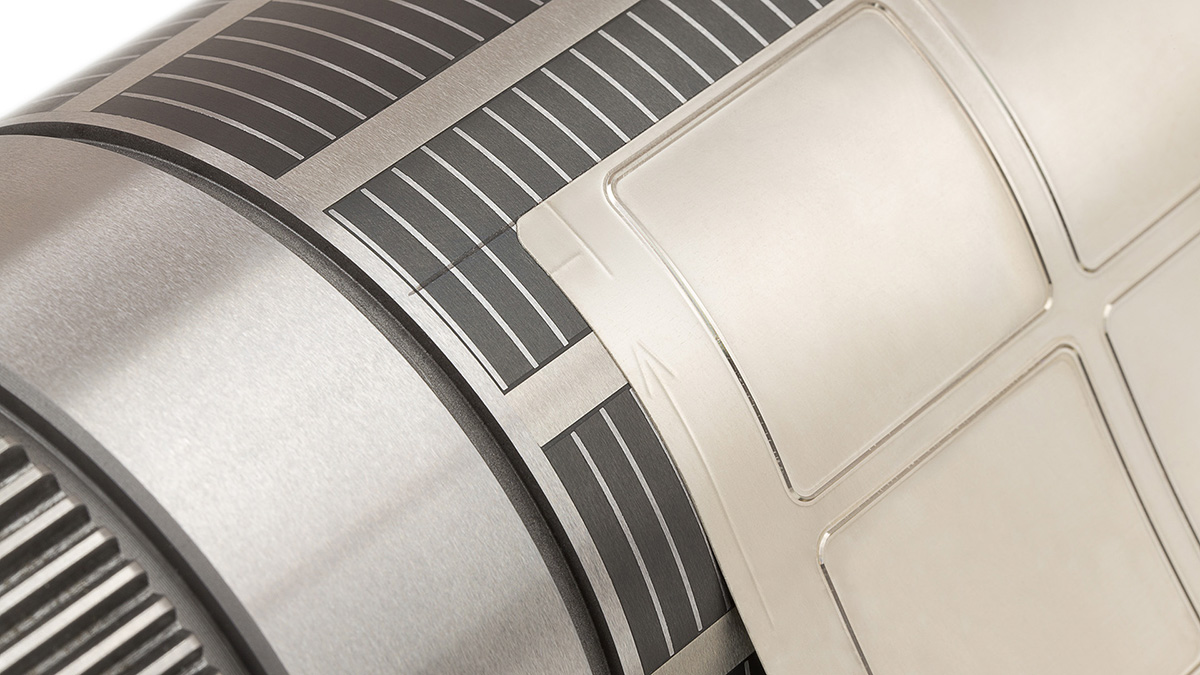

• A load cell such as the Tension Roll® Transducer

• A Pneumatic Brake, Magnetic Particle Brake, Clutch or Motor Drive System

Customers integrating tension control with a PLC most often utilize:

• A load cell signal amplifier such as the TA1 TrueTension™ Amplifier or TA500 Tension Amplifier

• A load cell such as the Tension Roll® Transducer, a pair of convertible load cells such as the Model C Series Transducers or Under Pillow Block Transducers such as the Model F Series

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

RESOURCES

Application Note: Rotary Die Cutting Tension Control (PDF)