Open-Loop vs Closed-Loop Tension Control: What Is The Difference?

An explanation of direct load cell feedback vs diameter calculation tension control systems.

DFE offers both open-loop and closed-loop automatic tension controllers to meet the application needs and budgets of almost all printers, converters and web processors.

The EasyWeb™ Torque Controller is an example of an open-loop tension controller. We call it a Torque Controller because that’s the variable it controls directly, while indirectly controlling tension on the web. The SteadyWeb™ 6 Tension Controller is an example of a closed-loop tension controller.

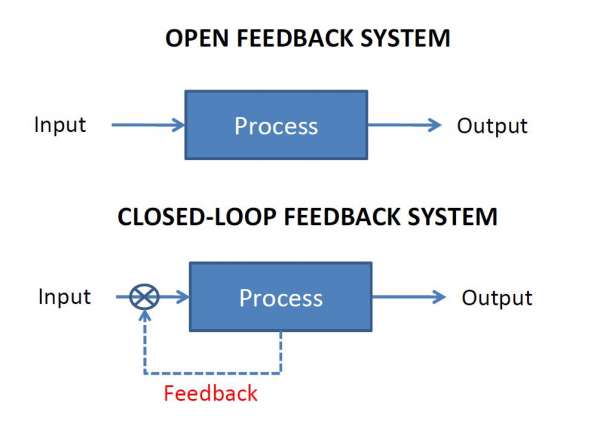

Conceptually, the difference between the two control systems is really just the element of feedback.

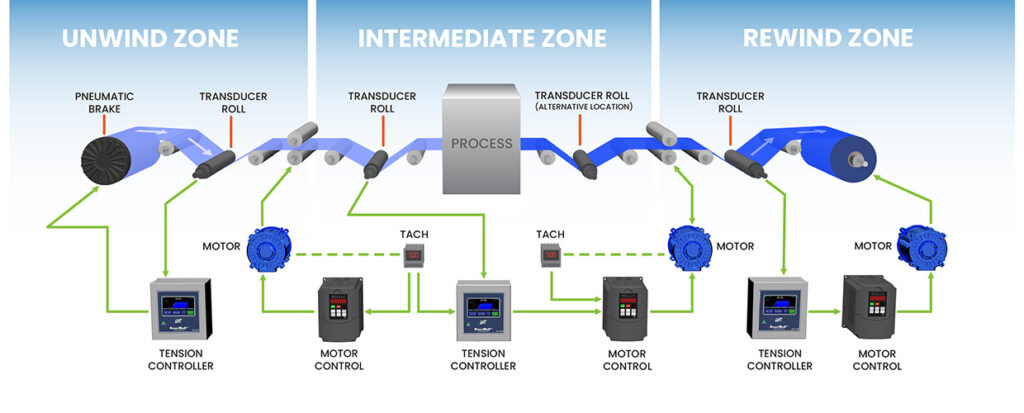

What differentiates the two control loop terms – open versus closed, is that a closed-loop system employs a feedback mechanism (tension sensing devices called tension transducers in our case) to directly measure the variable under control (web tension) and to transmit that measured value (our process feedback) back to the tension controller. A comparator circuit tells the controller to continuously adjust the web tensioning output so that the actual running web tension will match the desired tension setpoint that was input by the machine operator.

In the case of an open-loop controller, like the EasyWeb™ Torque Controller we’re achieving a similar continuous tension adjustment on the web as it’s being unwound or wound, but, instead of tension, the input for the controller is the calculated change in roll diameter as the rotating unwind roll decreases in diameter (or increases in diameter in the case of a driven rewind).

The signal for the roll diameter calculation can come from an ultrasonic sensor, an encoder or the ratio between line speed and roll speed tachometer readings. So, for our open-loop EasyWeb™ controller, the adjustment made to torque on the center-driven unwind (or rewind) is based on a variable other than direct tension measurement; thus the web tension on the moving web may be imprecise; but it may also be precise enough in many applications to prevent the kinds of tension-related problems (baggy web, wrinkling, stretching, web breaks, etc.) that cause waste.

So, the basic advantage of a closed-loop (feedback) vs open-loop (non-feedback) tension control system is its higher accuracy, and ability to react immediately to process disturbances and system noise. Because closed-loop tension control systems are continuously adjusting to actual measured tension, they are the best choice for applications with a low tolerance for material waste and applications that involve expensive extensible materials and films.

One of the only drawbacks to closed-loop tension control systems is that their sophisticated designs and requirements for direct tension measurement (from tension transducers or load cells) make them a bit more costly than open-loop controllers.

A lower-cost open-loop controller solution, like the EasyWeb™ Torque Controller, may perform well for many applications where a slight amount of tension deviation can be tolerated.

For further discussion on the subject of open-loop torque control, see this article from web handling expert, Tim Walker, of TJ Walker and Associates: Web Lines column on PFFC-online.com

Do you have a similar tension application that you would like to discuss?

Complete the form below and a DFE Applications Engineer will contact you shortly.

DFE does not share information with 3rd party advertisers.

RESOURCES